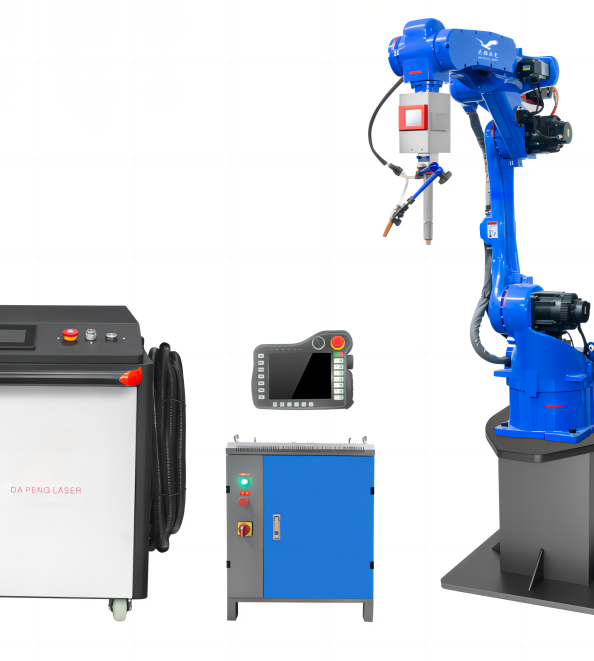

The Advanced Laser Cutting System of DP Laser Robots has been designed for precision and efficiency. This system uses highly advanced laser technology combined with robots that ensure fast cuts which are exact on various materials. Through automation, it simplifies production procedures thus increasing output while minimizing manual labor participation. This machine is flexible enough to handle complex tasks in large quantities making it an important tool for any modernized manufacturing setting. In addition to this feature, reliability is also a characteristic associated with the machine because once programmed correctly; it will never fail or make errors throughout its entire operational period. This solution from DP Lasers can easily blend into any current work process thereby bringing about creativity plus peak performance in organizations.

DP Laser is an innovative player in the area of laser cutting with a ban on robot laser cutting technology. The high efficiency of laser cutting is combined with advanced robotics in these systems enabling a high level of precision over a wide range of industrial applications. The robotic solutions designed by DP Laser are capable of dealing with complicated shapes and producing large quantities with high precision and repeatability. The high level of automation of control and the algorithms of the motion allow performing each cut consistently and saving material while enhancing productivity. Small details or large structural parts, in whichever case DP Laser is concerned their robot laser cutting technology has the flexibility and dependability that meets contemporary production standards. Staying ahead in regard to robot and laser technologies, DP Laser persists in expanding the frontiers in the market and presenting improvements in the way of work.

DP Laser's systems for cutting with a laser beam are praised for their versatility and flexibility in operating various types of cuts. They have such adaptability because they can work on different materials as well as complicated designs without any difficulty which reflects the brand's commitment to being flexible. Programmable robots and lasers whose parameters can be altered are among some of DP Lasers' creative ideas that allow users customize accurately depending on particular projects requirements. Businesses can therefore changeover between tasks and materials quickly thereby maximizing the use of their cutting systems since this kind of flexibility is exhibited by them With DP Laser, companies get a solution that grows with its production demands thus improving overall efficiency in operations.

More than anything else, DP Laser's products are known for being reliable — this is most apparent in their robot laser cutting systems. These machines have been created to work well even under difficult conditions found in industries; they were made tough. They can handle continuous use and heavy workloads because of how sturdy their build quality is and what materials were used during manufacture. What sets them apart from other companies' similar offerings though isn't just dependability but also comprehensiveness: DP offers an all-inclusive package with support services too such as customer care that responds quickly and technical aid when needed which gives businesses peace of mind knowing that there will always be someone ready to help them out if something goes wrong somewhere down the line. For this reason alone should one consider buying these kinds over others – not only do they last longer but also keep up higher levels of performance throughout their lifespan thus offering more value for money invested into them.

DP Laser uses the most cutting-edge laser technology in order to constantly set new industry standards. Their robot laser cutting systems are built with the latest features like high-precision lasers and intelligent robotic arms which enable them to cut more accurately at faster speeds on larger projects as well as smaller ones too if need be because all this integration has been done so that it can cater for both intricate and big scale works. It's systems have embedded advanced technologies designed to improve operational efficiency thus giving companies reliable tools for driving productivity According to DP Lasers continuous improvement policy its technological advancements not only meet but exceed what is required by current manufacturing needs thereby positioning itself as an industry leader in innovative laser solutions.

DP laser. Established in 2011, the company is headquartered in Shenzhen, Guangdong Province. There are currently 430 employees, with three major production bases located in Dongguan, Guangdong, Nantong, Jiangsu, and Jinan, Shandong. We have over 30 branches and offices in major cities in China, providing local sales, after-sales service, and exhibition halls.

RST Laser focuses onfiber laser cutting,laser welding,robot cutting and welding, standard and non-standard automated customized equipment, providing one-stop solutions.

The main engineers of DP Laser have over ten years of experience in the laser industry, and the company continuously invests a large amount of funds every year to research and develop new products and upgrade existing products, ensuring that the technical design and product quality are at the forefront of the industry.

The production base in Dongguan, Guangdong covers an area of 20000 square meters and has several large gantry milling machine processing centers,laser cutting machines,laser welding machines,robotic arms,laser marking machines, and other assembly and debugging workshops; The R&D center, CNC lathe processing center, and sheet metal processing center achieve full chain production of laser equipment.

The production base in Nantong, Jiangsu Province covers an area of 60 acres, with 13 floors of administrative office buildings, 30000 square meters of factory buildings, canteens, dormitories, underground parking lots, and other facilities.

The production base in Jinan, Shandong Province covers an area of 120 million square meters, mainly providing OEM services to top domestic factories such as Hgtech laser, Penta laser, etc.

DP Laser equipment is exported to more than 50 countries and regions around the world. In order to speed up overseas market layout, we provide brand agent franchise cooperation, OEM customization and other models. Welcome to negotiate.

Innovative laser systems deliver unmatched precision and speed.

Robust design ensures consistent, high-quality results in all operations.

Advanced technology minimizes energy use while maximizing output.

Dedicated customer service and technical support for seamless integration.

The DP Laser Advanced Robotic Laser Cutting System can process a wide range of materials, including metals, plastics, and composites. Its versatile design allows for high-precision cutting of various material types and thicknesses.

The robotic system enhances cutting efficiency by automating the cutting process, which increases speed and consistency. It reduces manual handling and errors, leading to higher throughput and improved overall productivity.

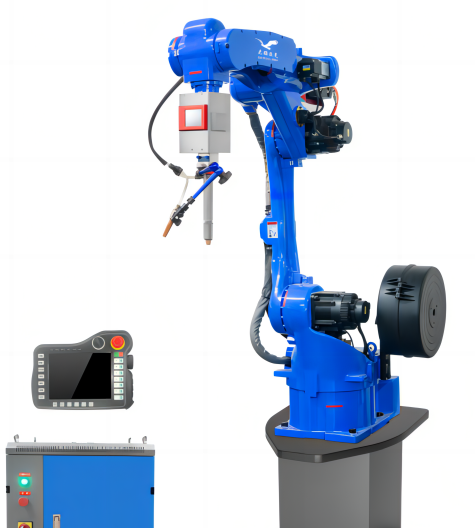

Key features include advanced robotic arms for precise movement, high-performance laser technology for accurate cuts, and automated controls for seamless integration. The system also offers flexibility to handle complex shapes and high-volume production.

Maintenance involves regular inspections of the robotic arms, laser components, and control systems. The system includes diagnostic tools to identify potential issues early. Routine tasks include cleaning optical components and checking alignment to ensure optimal performance.

Yes, the system is designed for easy integration into existing production lines. It features flexible connectivity options and can be programmed to work with other equipment. Our technical support team assists with the integration process to ensure a smooth setup.