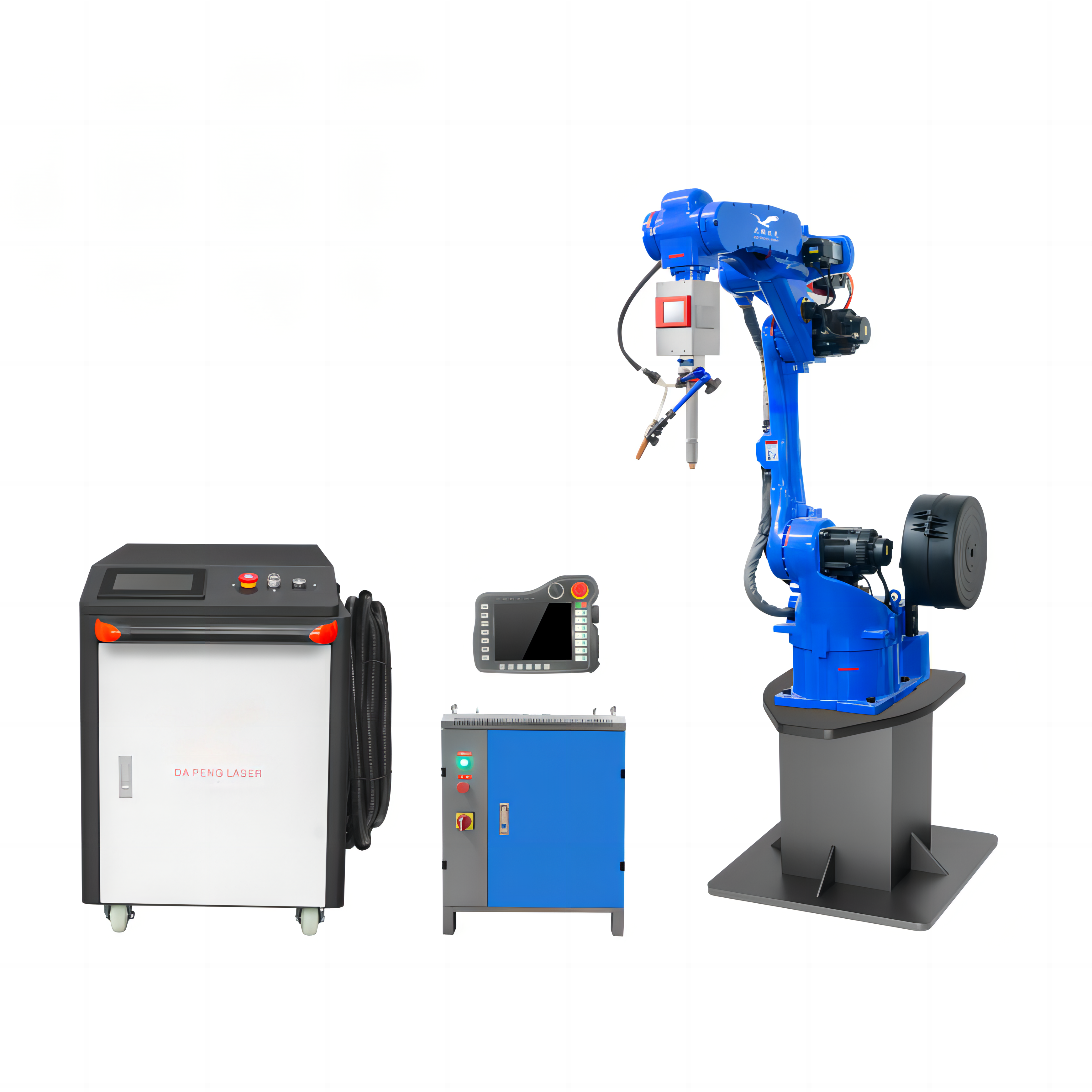

The DP Laser Precision Robotic Laser Welding System is meant for welding with high accuracy which utilizes improved automation. This system integrates cutting-edge laser technology and advanced robotic arms to ensure uniformity of weld quality in different materials. The need for manual involvement and operation errors during production are eliminated hence improving efficiency. It has friendly user interface coupled with the ability to integrate, therefore making it suitable for use in complex as well as high-volume welding applications that require reliability under tough industrial conditions. DP Laser system is a major milestone towards automated welding solutions.

DP Laser is famous for being accurate and efficient in robot laser welding. It designs its systems so that they can perform exceptionally well when it comes to accuracy during welding by using state-of-the-art lasers alongside advanced robotics. Every single one of these machines has been made very carefully with lots of details put into them; this guarantees high-quality strong joints after every weld. What is more, precise controls are integrated into the system by DP Laser which allows real-time adjustments and fine tuning thereby giving best results possible on any welding tasks across different materials. Such dedication towards achieving perfection wouldn't be complete without having an eye on performance too; hence DP Laser ensures all its products are able to withstand tough conditions within modern manufacturing setups where reliability matters most.

DP Laser's robot laser welder machines are considered to be reliable and durable as they are built for use in high volume production environments. Each one is constructed with strong materials and engineering methods which ensure that it will last long without requiring frequent servicing. The fact that the equipment can stay operational for extended periods indicates the company's commitment to quality; it can operate round the clock even under heavy loads without losing its precision or slowing down. Additionally, DP Laser provides comprehensive maintenance coverage so that facilities experience minimal downtime while attaining maximum productivity levels. Such insistence on reliability has earned this brand favor from many quarters seeking trustworthy and durable welding solutions.

When it comes to joining materials together using lasers, DP Laser more than makes it possible with the help of some of the most advanced joining technologies. The design of the robotic laser welding equipment developed by our company is focused on obtaining a high-quality weld with deep penetration in different types of industries and materials. While pairing DP Laser’s laser with the latest robotic technology, accurate motion control and dependability are achieved, allowing to perform intricate welding tasks with minimal effort. Peter Thibaut Welding Systems Inc's staff builds systems that are operating effectively under industrial conditions and are durable in service. DP Laser not only improves scanning speed – height and motion control in z-axis – but also reduces the time required to complete the welding processes. There is no research and development or modifications of the already existing welding units; rather each welding solution offered has been creatively designed to respond to the current demands of the manufacturing processes so that strength and flexibility are assured when it comes to even the toughest welding applications.

DP Laser is a pioneer in robot laser welding technology. Their systems use state-of-the-art laser and robotics technology, which means businesses get modern solutions that increase efficiency. High-speed lasers, intelligent control systems and improved cooling techniques have all been integrated into their products as part of an ongoing commitment to innovation at DP Laser. The brand continuously invests in R&D so that its welding systems are equipped with the latest features available on the market today – this helps companies stay ahead of rivals and achieve better manufacturing outcomes.

DP laser. Established in 2011, the company is headquartered in Shenzhen, Guangdong Province. There are currently 430 employees, with three major production bases located in Dongguan, Guangdong, Nantong, Jiangsu, and Jinan, Shandong. We have over 30 branches and offices in major cities in China, providing local sales, after-sales service, and exhibition halls.

RST Laser focuses onfiber laser cutting,laser welding,robot cutting and welding, standard and non-standard automated customized equipment, providing one-stop solutions.

The main engineers of DP Laser have over ten years of experience in the laser industry, and the company continuously invests a large amount of funds every year to research and develop new products and upgrade existing products, ensuring that the technical design and product quality are at the forefront of the industry.

The production base in Dongguan, Guangdong covers an area of 20000 square meters and has several large gantry milling machine processing centers,laser cutting machines,laser welding machines,robotic arms,laser marking machines, and other assembly and debugging workshops; The R&D center, CNC lathe processing center, and sheet metal processing center achieve full chain production of laser equipment.

The production base in Nantong, Jiangsu Province covers an area of 60 acres, with 13 floors of administrative office buildings, 30000 square meters of factory buildings, canteens, dormitories, underground parking lots, and other facilities.

The production base in Jinan, Shandong Province covers an area of 120 million square meters, mainly providing OEM services to top domestic factories such as Hgtech laser, Penta laser, etc.

DP Laser equipment is exported to more than 50 countries and regions around the world. In order to speed up overseas market layout, we provide brand agent franchise cooperation, OEM customization and other models. Welcome to negotiate.

Innovative laser systems deliver unmatched precision and speed.

Robust design ensures consistent, high-quality results in all operations.

Advanced technology minimizes energy use while maximizing output.

Dedicated customer service and technical support for seamless integration.

The DP Laser Precision Robotic Laser Welding System can weld a variety of materials, including metals like steel, stainless steel, aluminum, and alloys. Its advanced technology ensures high-quality welds across different material types and thicknesses.

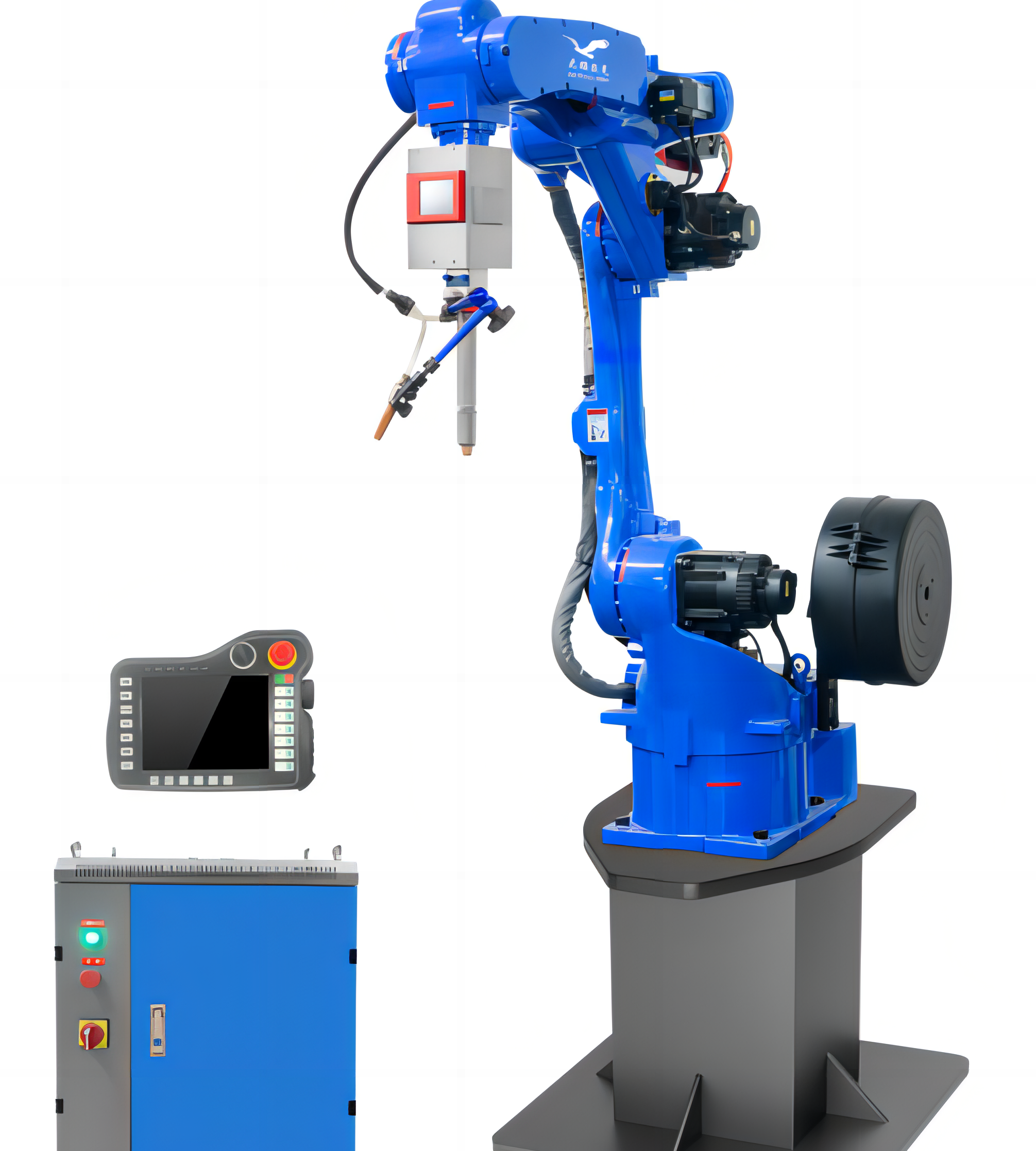

The robotic system enhances welding precision through its advanced robotic arms and precise motion control. It allows for accurate placement and movement of the laser, ensuring consistent weld quality and reducing errors in complex and high-volume applications.

Key features include high-performance robotic arms for accurate welding, advanced laser technology for superior weld quality, and an automated control system for reduced manual intervention. The system also offers integration flexibility with existing production lines.

Maintenance includes regular checks of the robotic arms, laser components, and control systems. Routine tasks involve cleaning optical components, verifying alignment, and ensuring proper calibration. The system also includes diagnostic tools for early detection of potential issues.

Yes, the DP Laser Robotic Laser Welding System is designed for seamless integration with other equipment. It features flexible connectivity options and can be easily programmed to work with existing machinery, enhancing overall production efficiency.