Equipment Characteristics

1. Adopt high precision rack and pinion and linear guide, with smooth transmission and high precision. It can better ensure the stability of machine operation and the service life of transmission parts.

2. The laser tube cutting machine adopts U-type beam structure, and the machine tool adopts the whole square and plate mixed welding structure. The use of 600°C high temperature heat treatment, 24 hours with the furnace cooling, roughing after annealing, and then vibration aging treatment, can completely eliminate the internal stresses of welding and processing. With 12 m gantry milling semi roughing and finishing, the machine has good rigidity, high precision and good bending torque resistance and can be used for a long time without deformation. Z-axis adopts the whole cast aluminum structure, with light weight, fast dynamic response, and more in line with high-speed machining and acceleration.

3. X/Y/Z/W1/W2 axes all adopt high-performance servo motors with high precision, high speed, large torque and large inertia, and stable and durable performance, which ensures the structure of the whole machine is stable, good rigidity, light weight and high dynamic response.

4. The front and rear chucks are 4-jawed and adopt pneumatic structure to clamp the pipes, carrying out 2-2 symmetrical movements and automatic centering without manual re-centering; a regulator is installed, and the air pressure is adjusted at any time.

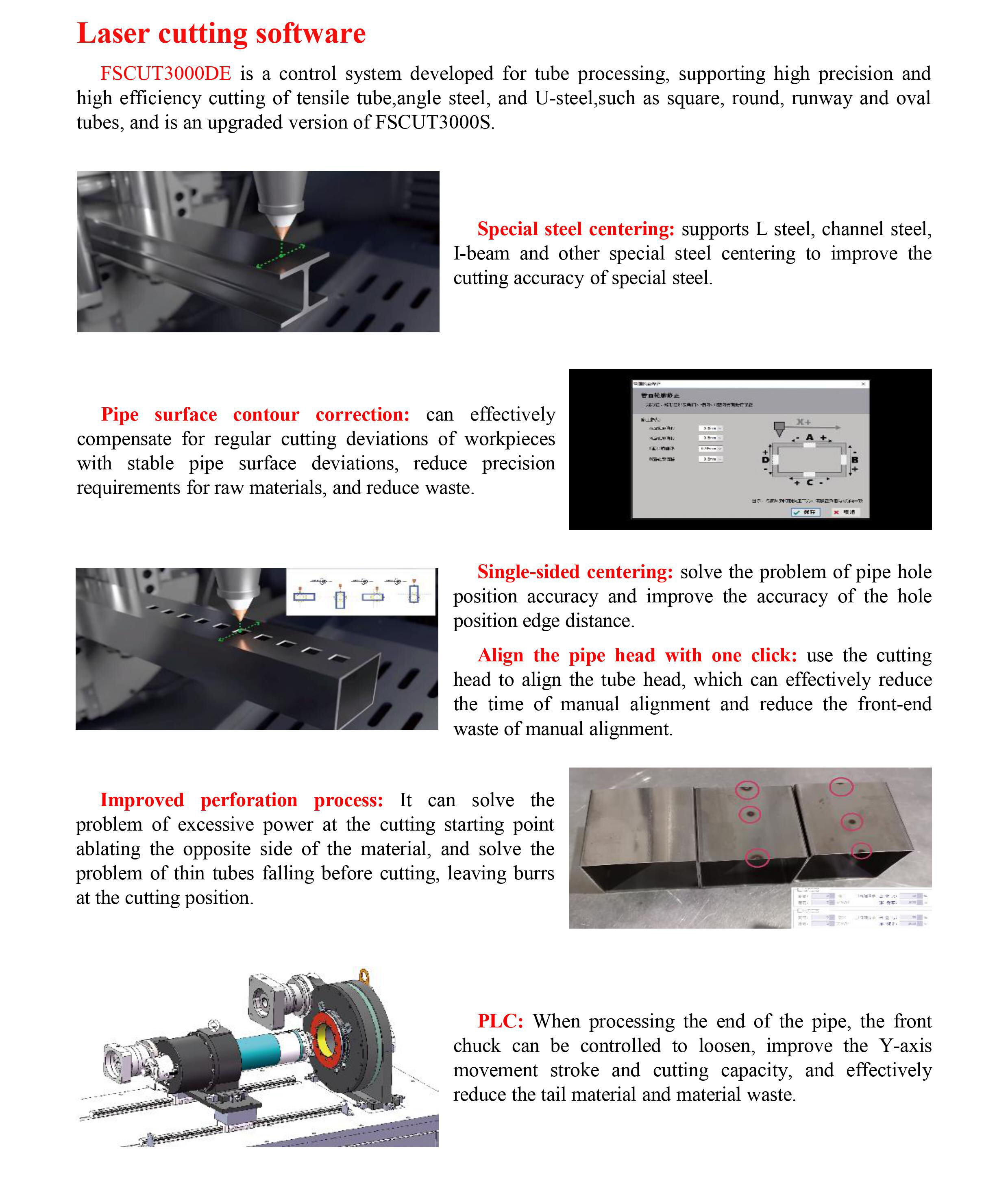

5. Adopt FSCUT3000, a special windows-based CNC system for fiber laser tube cutting machine by Friendess Electronics, which integrates a lot of special function modules for laser cutting control, with powerful functions, good man-machine interface and simple operation.

6. The expert version of nesting software, dedicated to Friendess FSCUT3000 CNC system, is the core technology of CNC cutting machine to realize "full-time cutting, high-efficiency cutting and high nesting rate cutting", and it is the fundamental guarantee to effectively save materials and improve cutting efficiency.

7. Cutting head can choose the fiber laser cutting head and capacitive sensing of the international famous brand WSX, which has high sensing precision, sensitive response and the most stable and reliable performance.

8. Adopt high-precision electronically-controlled proportional valve, which can precisely control the air pressure of cutting auxiliary gas to achieve the best cutting effect.

9. The dust extraction system in front of the cutting area can effectively removes a large amount of dust generated during cutting, which provides a good working space for personnel.

10. The whole machine is highly integrated, with good system performance, high life expectancy, high cutting precision and low operating costs, and it meets the needs of 24 hour industrial production needs.