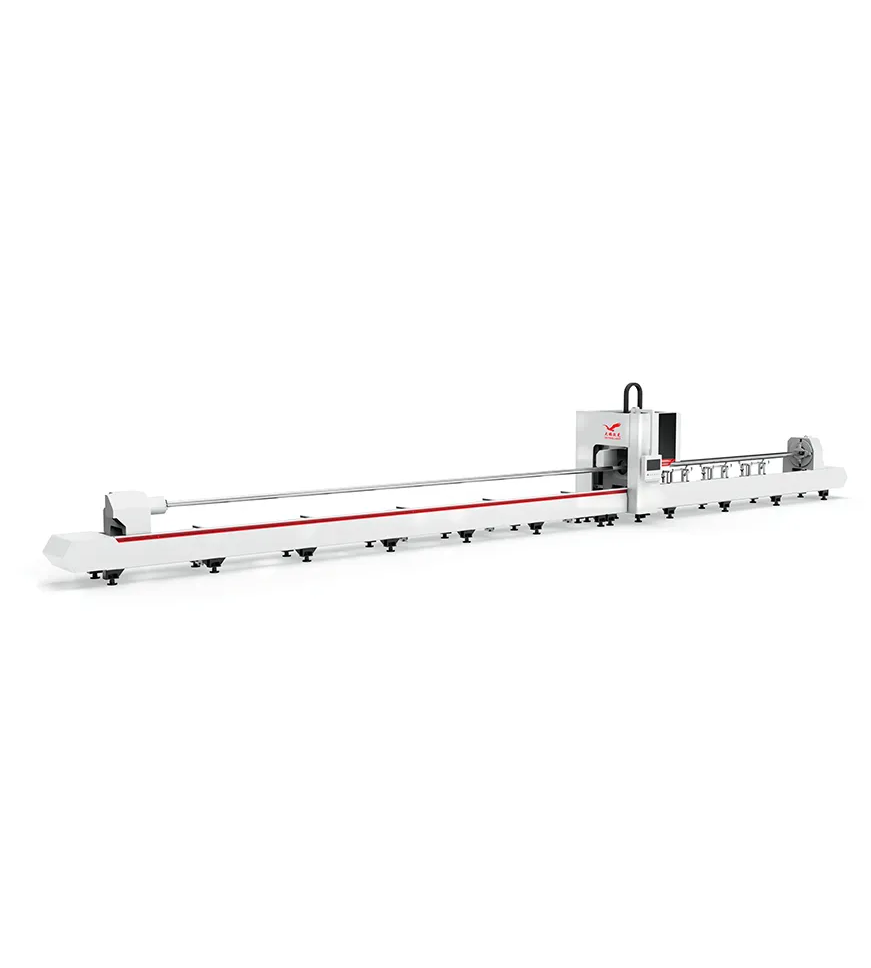

With greater precision and productivity in mind, the DP Laser High-Performance Fiber Laser Cutting Machine offers itself. This machine boasts of fast and accurate cuts that do not waste much material; thus making it suitable for many industrial uses. It is built to last through any kind of work with modern production demands as its reliability never fails due to advanced technology used while making this product. When using this device one can always expect good results since they are always consistent no matter what type of metal or composite needs cutting because every single time you will get top quality output if only it was done correctly by following instructions carefully and aligning components properly.

DP Laser is famous for the most advanced technology in the fiber laser cutting machine industry. They incorporate up-to-date lasers and motion control systems that no other company has integrated yet to ensure more precision and faster speed. What makes them different is their commitment to being innovative; this means all of their machines can cut through any material quickly without sacrificing quality. DP Laser uses modern optics along with sophisticated software algorithms so users have access not only tools meeting but surpassing industry standards too – in other words everything required for success! This also creates machines which perform better than others on reliability or durability thus making them ideal even during heavy duty industrial applications.

The fiber laser cutting machines of DP Laser are made for easy using. They do this by including simple controls and high-level automation features that make operation easier and improve efficiency at the same time. DP Laser has equipped its machines with interfaces that are friendly to users, as well as software which is advanced enough to simplify setup and operation hence enabling desired results to be achieved quickly. The company's emphasis on simplicity does more than just reduce training periods; it also increases productivity within production settings themselves. In this way, through putting the user first in line of importance, DP Lasers ensures that businesses can access cutting-edge technology without too much complexity or difficulty thereby allowing them to maximize their operational potentialities.

DP Laser fiber laser cutting machines are characterized by durability and robustness. The construction is strong and the materials used in making these machines are of high quality, which was done keeping in mind that they should sustain heavy workloads and continuous use. DP Laser also ensured that their systems could be employed under tough conditions by designing them well with engineering knowledge; this guarantees reliability over long periods without frequent breakdowns or repairs being required. Moreover, due to its rugged design feature, diverse materials can be processed on this machine thereby allowing for versatility when dealing with intricate cutting tasks thus making it ideal for companies looking forward to consistent performance from their equipment even after many years of service life.

At DP Laser, we pride ourselves in precision engineering as each of our fiber laser cutting machine is made with accuracy in mind. Our machines are design with great care in order to achieve good quality and exactly defined cuts for materials such as stainless steel and aluminum when needed. This accuracy is not a luxury but a value ingrained within the corporate identity of laser technologies. See moreOur fiber laser cutting machines can be employed to achieve the required level of accuracy whether it is a small detailed design or a major undertaking. The laser technology which has become a feature in every machine produced by DP Laser has also ensured that the post processing efforts aimed at reducing the distortion of the product are kept to a bare minimum and the production efficiency is improved. For those whose waiver standard and demand precision, DP Laser is the ultimate solution which guarantees that such expectation is met in every cut made.

DP laser. Established in 2011, the company is headquartered in Shenzhen, Guangdong Province. There are currently 430 employees, with three major production bases located in Dongguan, Guangdong, Nantong, Jiangsu, and Jinan, Shandong. We have over 30 branches and offices in major cities in China, providing local sales, after-sales service, and exhibition halls.

RST Laser focuses onfiber laser cutting,laser welding,robot cutting and welding, standard and non-standard automated customized equipment, providing one-stop solutions.

The main engineers of DP Laser have over ten years of experience in the laser industry, and the company continuously invests a large amount of funds every year to research and develop new products and upgrade existing products, ensuring that the technical design and product quality are at the forefront of the industry.

The production base in Dongguan, Guangdong covers an area of 20000 square meters and has several large gantry milling machine processing centers,laser cutting machines,laser welding machines,robotic arms,laser marking machines, and other assembly and debugging workshops; The R&D center, CNC lathe processing center, and sheet metal processing center achieve full chain production of laser equipment.

The production base in Nantong, Jiangsu Province covers an area of 60 acres, with 13 floors of administrative office buildings, 30000 square meters of factory buildings, canteens, dormitories, underground parking lots, and other facilities.

The production base in Jinan, Shandong Province covers an area of 120 million square meters, mainly providing OEM services to top domestic factories such as Hgtech laser, Penta laser, etc.

DP Laser equipment is exported to more than 50 countries and regions around the world. In order to speed up overseas market layout, we provide brand agent franchise cooperation, OEM customization and other models. Welcome to negotiate.

Innovative laser systems deliver unmatched precision and speed.

Robust design ensures consistent, high-quality results in all operations.

Advanced technology minimizes energy use while maximizing output.

Dedicated customer service and technical support for seamless integration.

The DP Laser Fiber Laser Cutting Machine can process a wide range of materials, including various metals (such as steel, aluminum, and stainless steel) and composites. It is designed to handle different thicknesses and types of materials, making it versatile for various industrial applications.

The DP Laser Fiber Laser Cutting Machine utilizes advanced laser technology and high-speed motion control systems to ensure precision. It features high-resolution optics and a stable cutting platform, which together guarantee accurate and consistent cuts, even for intricate designs.

The maximum cutting thickness of the DP Laser Fiber Laser Cutting Machine depends on the material being processed. Generally, it can cut up to 25mm for mild steel and up to 15mm for stainless steel. For exact specifications, please refer to the technical datasheet or consult with our sales team.

The DP Laser Fiber Laser Cutting Machine is designed for minimal maintenance with robust components and self-diagnostic systems. Regular maintenance includes checking the laser optics and cooling systems. Downtime is minimized due to the machine's reliable construction and advanced monitoring features that alert operators to potential issues before they become critical.

Yes, the DP Laser Fiber Laser Cutting Machine is designed for easy integration into existing production lines. It features flexible connectivity options and an intuitive control system that allows for seamless integration with other equipment and automated systems. Our technical support team is available to assist with the installation and setup process.