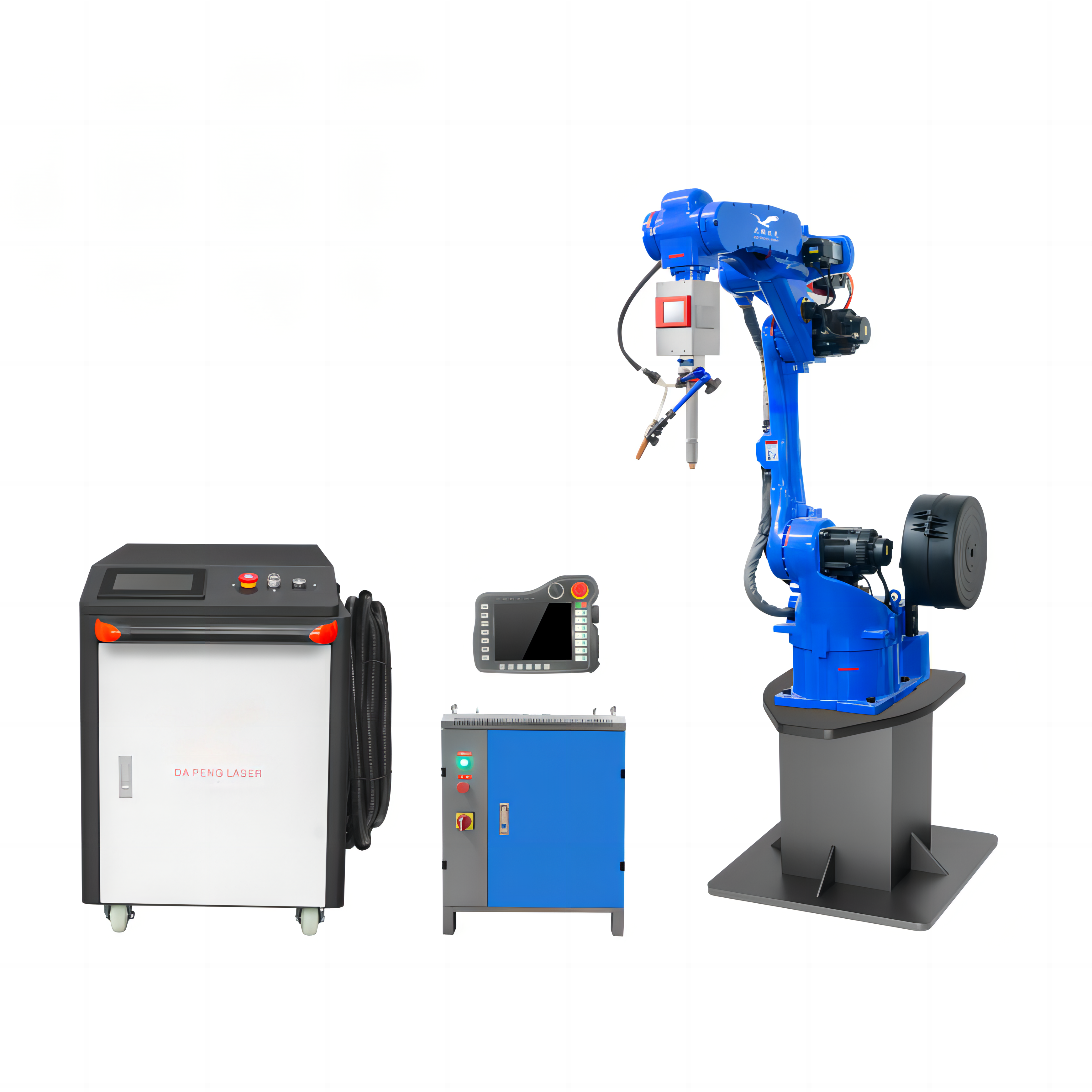

Explore DP LASER's comprehensive range of high-quality laser welding robots. Our portfolio features automated laser welding robots, assembly robots, and automated remote-controlled models, among others. Each robot is designed with advanced technology to ensure precise and efficient welding, meeting the diverse needs of industrial applications. Trust DP LASER for reliable, innovative, and high-performance laser welding robots.

DP laser. Established in 2011, the company is headquartered in Shenzhen, Guangdong Province. There are currently 430 employees, with three major production bases located in Dongguan, Guangdong, Nantong, Jiangsu, and Jinan, Shandong. We have over 30 branches and offices in major cities in China, providing local sales, after-sales service, and exhibition halls.

RST Laser focuses onfiber laser cutting,laser welding,robot cutting and welding, standard and non-standard automated customized equipment, providing one-stop solutions.

The main engineers of DP Laser have over ten years of experience in the laser industry, and the company continuously invests a large amount of funds every year to research and develop new products and upgrade existing products, ensuring that the technical design and product quality are at the forefront of the industry.

The production base in Dongguan, Guangdong covers an area of 20000 square meters and has several large gantry milling machine processing centers,laser cutting machines,laser welding machines,robotic arms,laser marking machines, and other assembly and debugging workshops; The R&D center, CNC lathe processing center, and sheet metal processing center achieve full chain production of laser equipment.

The production base in Nantong, Jiangsu Province covers an area of 60 acres, with 13 floors of administrative office buildings, 30000 square meters of factory buildings, canteens, dormitories, underground parking lots, and other facilities.

The production base in Jinan, Shandong Province covers an area of 120 million square meters, mainly providing OEM services to top domestic factories such as Hgtech laser, Penta laser, etc.

DP Laser equipment is exported to more than 50 countries and regions around the world. In order to speed up overseas market layout, we provide brand agent franchise cooperation, OEM customization and other models. Welcome to negotiate.

Innovative laser systems deliver unmatched precision and speed.

Robust design ensures consistent, high-quality results in all operations.

Advanced technology minimizes energy use while maximizing output.

Dedicated customer service and technical support for seamless integration.

Yes, Samples require cost payment (deductible from bulk orders)Full test reports provided.

Full-chain customization services:Equipment shell laser engraving enterprise LOG0 (support Pantone color matching) Function customization: develop exclusive process modules according to industry needs (technical specifications are required) System: Multi-language interface customization.

Dual-base globalmanufacturing network. Nantong Base (Jiangsu): 90 acres Specialization: High-power cutting machines/automated production lines. Dongguan Base (Guangdong):40,0008 Specialization: Export-standard laser cutters/bendingequipment/automated lines/Virtual tour: On-site inspection (CNC centers/laser labs) via online meeting arranged within 72hrs aftel booking.

Three-tier capacity assurance: Equipment Type(Standard) Monthly Capacity Emergency Scalability Laser Cutters 80+mnthl +30%(25-day lead time) Laser Welders 120+mnthly +50%7-day notice for peak seasons Automated Lines 15 lines +20%(30-day delivery) Data credibility: 25,000+ units delivered over 13 years Annual capacity: 20,000+ units

Standard models: 15-20 workdays (incl.calibration) Custom orders: 25-30 days for welders/cutters (30% faster than industry av.erage) Global logistics: Sea freight: 25 days to port + end-to-end installation Support:24/7 technical response