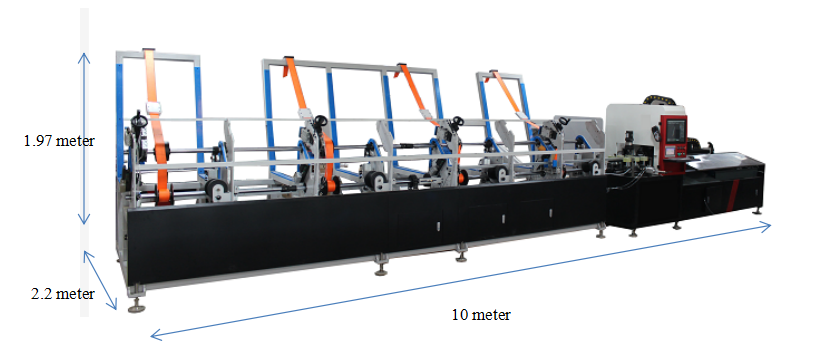

3D Laser tube cutting host + automatic feeding table

(Auto feeding suit for round pipe≤φ90mm,Square≤63mm)

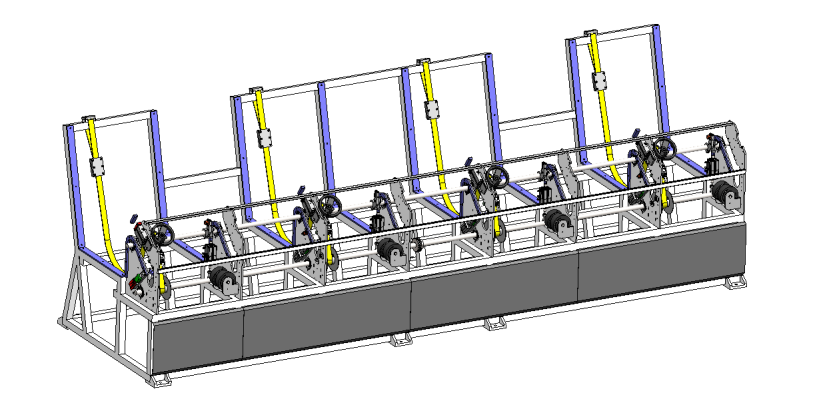

Feeding frame optional

Feeding frame optional

For square,round pipe auto feeder:Apply to diameter 15-89mm round pipe,15*15-63*63mm square pipe

Features of Bote Equipment:

Features of Bote Equipment:

1、Full automatic feeding

Fully automatic feeding of the whole bundle. It is only necessary to hoist 6 meters of raw materials into the storage rack in batches to achieve: automatic uploading → automatic feeding → automatic cutting → automatic blanking of the whole process.

2、High efficiency and easy operation:

This machine is only for cutting small and medium-sized pipe and square pipe, the structure is stable; when changing the pipe diameter, it is necessary to replace the chuck and adjust the center height of the pipe through the handwheel device.

3、The blind area of tailings is small, saving materials and reducing post-processes:

Simple and unique feeding method, when the pipe is in the feeding machine and cannot continue to feed, the subsequent pipe will continue to push the current pipe to continue feeding to complete the cutting of tailings. The machine normally cuts tailings is 40mm-70mm, saving material loss and eliminating tailings processing process.

Laser generator: Max/ Raycus

Premium beam quality

Maintenance-free operation

constant over the entire power range

Large working format, small focal length

Efficiency > 30%

Integrated coupler or beam switch options

Laser cutting head: Ospri

This cutting head has strong advantages in high-power

large-format fiber laser cutting applications.

The internal structure of the laser head is completely sealed,

which can prevent the optical part from being polluted by dust.

The laser head adopts two-point centering adjustment and

focus collimating mirror adjustment method.

Driven by imported motor, the efficiency in perforation is significantly improved.

The protective lens is installed in a drawer, which is easy to replace.

Modular design, high precision and easy maintenance.

Main purpose and scope of application

Laser cutting is a more advanced processing method in material processing. The laser pipe cutting machine produced by our company is mainly used for cutting and blanking of round pipes, such as 304# stainless steel pipe, 201# stainless steel pipe, galvanized pipe, brass pipe, aluminum pipe and other metal pipes. The cutting speed is fast, the efficiency is high, the product incision is flat, and there is no burr.

Note: According to the selected laser power, the cutting range of the material is different.

Use environmental conditions

1) Specifications of power supply: pipe diameter below 70: 220V, 50Hz, stable voltage.Pipe diameter above 70: 380V, 50Hz, stable voltage

2) Grounding protection: The machine tool is grounded, and ground piles are grounded on the machine side. The machine tool can also be connected to the ground wire of the power supply, and the grounding resistance is required to be less than 4Ω.

3) External air source: It consists of air compressor, air storage tank, refrigerated compressed air dryer and compressed air precision filter.

The following are the recommended parameters of the air source:

|

Screw Air Compressor

|

Gas tank

|

|

Power:15KW

|

Volume flow

:1.2m³/min

|

Volume:0.6 m

|

Design pressure

:1.6Mpa

|

|

Voltage:380V

|

Work pressure

:1.6Mpa

|

|

|

|

Refrigerated compressed air dryer

|

Compressed air precision filter

|

|

Refrigerant:R22

|

Use pressure

:1.6Mpa

|

Grade:AA

|

Work pressure

:≤1.6Mpa

|

|

|

Handling air volume

:2.6m³/min

|

Impurity particle size

:0.01 micron

|

Residual oil

:0.001ppm

|

The air compressor can be placed outdoors, but it should be within 10 meters from the pipe cutting machine to ensure a stable air supply.

4) Site requirements: The installation foundation requires that there should be no large vibration around.

5) The function of the chiller: it is used for cooling lasers, cutting heads, QBH and other special equipment, and the cooling circulating water requires the use of high-quality pure water or distilled water;

6) Reserved space: the distance between the back and rear of the machine tool and the workshop wall should be more than 1.0 meters

7) Environmental requirements: The control unit, servo unit, display and control panel are the core components of the machine tool, which have certain requirements for the environment, and the machine tool should be prevented from being interfered by electromagnetic waves, such as arc welding and electric discharge machining machines, so as to affect the normal operation of the machine tool work.