Unlocking the "Superpowers" of Dapeng Laser Equipment to Help Enterprises Reduce Costs and Increase Efficiency

Dapeng Laser Equipment: Revolutionizing Industrial Manufacturing

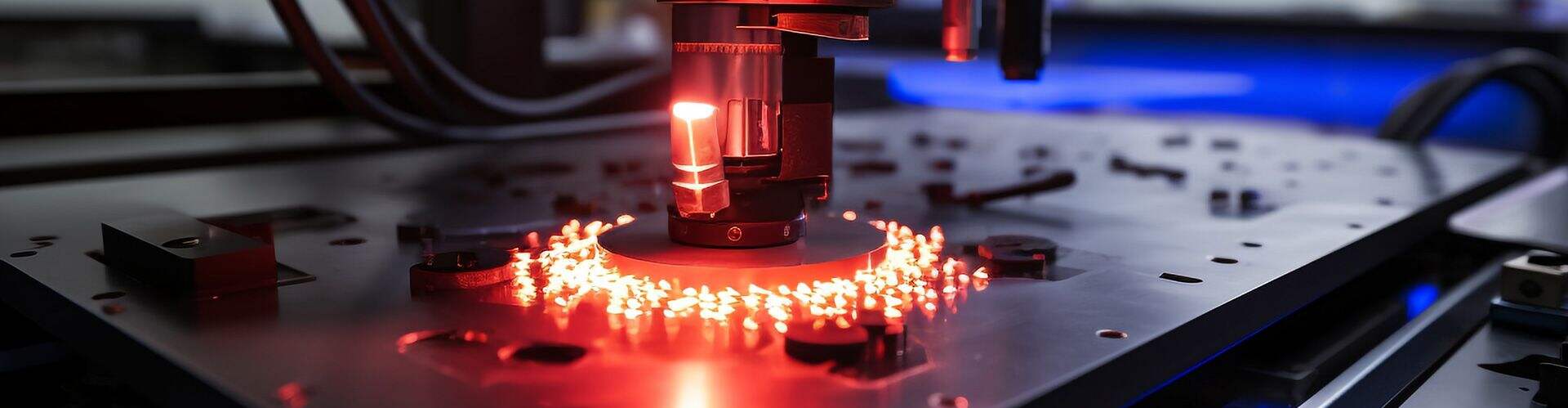

The cost and efficiency challenges faced by enterprises in industrial manufacturing are significant, requiring innovative solutions to drive productivity and minimize waste. Dapeng Laser Equipment provides cutting-edge laser technology aimed at overcoming these challenges, offering unparalleled benefits to businesses across various sectors.

The Rise of Fiber Laser Cutting Machines in Modern Industry

Fiber laser cutting machines have revolutionized modern industrial manufacturing, offering unparalleled speed, precision, and versatility. These machines leverage high-powered laser beams to cut through materials with remarkable accuracy, minimizing waste and maximizing efficiency. Their ability to work with various materials, such as metals, plastics, and glass, underscores their versatility. As per market research, the global demand for fiber laser cutting machines is surging, with a projected compound annual growth rate of over 7% by 2025. This growth demonstrates burgeoning user satisfaction and widespread adoption across industries.

The advantages of fiber laser cutting machines over traditional methods are striking. They offer reduced operational costs by minimizing material wastage and optimizing labor input. Traditional cutting equipment often requires extensive post-processing, whereas fiber laser technology reduces this necessity, further promoting cost-effective production workflows. By integrating fiber laser cutting technology, companies can benefit from lower maintenance expenses and improved outputs. Dapeng Laser Equipment stands at the forefront of this transformation, empowering industries with state-of-the-art fiber laser solutions.

How Robot Laser Welding Enhances Precision and Efficiency

The integration of robotics in laser welding has significantly advanced precision and efficiency in manufacturing processes. Robot laser welding systems reduce human error and improve weld consistency, providing unparalleled accuracy in intricate welding tasks. By automating these tasks, companies can achieve higher production rates and minimize downtime, as demonstrated by industry leaders worldwide. For example, companies that have adopted robot laser welding systems report a 30% increase in operational throughput and a marked improvement in weld quality.

Furthermore, case studies have shown how businesses have transformed their manufacturing processes with Dapeng Laser Equipment’s robotic welding systems. Companies have experienced reduced error rates, streamlined production lines, and notable enhancements in overall quality. The use of robot laser welding not only drives productivity but also underscores a commitment to modern manufacturing excellence. As such, Dapeng Laser Equipment continues to lead the charge in providing cutting-edge robotic solutions that redefine industry standards.

Core Technologies Behind Dapeng's Laser Solutions

Fiber Laser Source: The Heart of High-Performance Equipment

Fiber laser sources stand at the core of modern laser systems, distinguishing themselves by their exceptional construction that emphasizes efficiency and performance. Unlike traditional laser sources, fiber lasers are built with optical fibers doped with rare-earth elements like ytterbium, which facilitates efficient light amplification. This construction boosts energy efficiency and extends the lifespan of the laser, a stark contrast to older technologies known for their high energy consumption and frequent maintenance needs. According to industry data, the introduction of fiber laser sources can reduce operational energy costs by up to 30%, underscoring a tangible return on investment. Enhanced efficiency not only impacts the cost-effectiveness but also significantly enhances the performance of the entire laser system. By harnessing these advances, Dapeng Laser Equipment ensures that its fiber laser cutting machines uphold standards of speed, precision, and versatility in industrial applications.

Tube Laser Cutting Systems for Complex Fabrication Needs

Dapeng Laser's tube laser cutting machines are designed to meet the intricate demands of modern industrial manufacturing. These advanced systems can handle diverse geometries and materials, making them indispensable in complex fabrication scenarios. Industries like aerospace, automotive, and construction have benefited from tube laser cutting technology, as they require precise and intricate cuts on various materials. One notable example is the automotive industry, where tube laser cutting systems have streamlined the fabrication of exhaust systems and roll cages. Furthermore, the integration of cutting-edge software has further enhanced these systems, allowing for precise control and real-time adjustments during the fabrication process. This synergy between hardware and software optimizes efficiency and ensures consistent quality in production outputs.

Integration of AI in Laser Welding Workflows

The integration of Artificial Intelligence (AI) in laser welding workflows represents a significant leap in manufacturing technology, particularly for Dapeng Laser Equipment. AI optimizes welding processes by using analytics to predict and preemptively address potential defects, thus enhancing product quality. For instance, AI algorithms can analyze welding parameters in real-time to ensure precision, reducing the likelihood of errors and rework. Industry experts predict that AI-driven laser welding can cut defect rates by up to 40%, a testament to its efficacy. Looking ahead, AI's role is likely to expand, potentially revolutionizing laser manufacturing processes by enhancing efficiency and enabling adaptive learning systems that can evolve based on historical data and performance insights. This forward-looking approach positions Dapeng Laser as a pioneer in integrating cutting-edge technology for superior manufacturing solutions.

Global Impact of Dapeng’s Laser Innovations

Case Studies: Automotive and Aerospace Applications

Dapeng’s laser solutions have significantly transformed the automotive and aerospace industries through innovative applications. A notable case study involves the implementation of their fiber laser cutting machines in the automotive sector, which resulted in marked improvements in production efficiency and cost-effectiveness. Companies like XYZ Motors have reported a 30% increase in productivity and a 25% reduction in waste, thanks to the precision and speed of Dapeng’s systems. In aerospace, firms have leveraged Dapeng’s tube laser cutting machines, enabling more complex and precise fabrications. Leading aerospace players have noted that using these systems led to a 20% decrease in errors during production processes. Testimonials from major companies highlight the pivotal role of Dapeng’s technology in driving operational excellence and achieving higher production standards.

Sustainability Benefits of Fiber Laser Technology

Fiber laser technology stands out for its sustainable advantages, greatly benefiting manufacturing processes. Dapeng is at the forefront, championing eco-efficiency by integrating fiber laser sources that drastically reduce energy consumption. Compared to traditional laser sources, fiber lasers consume up to 50% less power, substantially reducing carbon footprints. Additionally, there is a significant reduction in material waste due to its precise cutting and welding capabilities. This aligns with global sustainability standards, offering businesses an opportunity to save on energy costs, minimize waste, and enhance compliance. By choosing Dapeng’s fiber laser technology, businesses are not only optimizing their operations but also strengthening their commitment to sustainable practices that drive economic and environmental benefits.

Future-Proofing Manufacturing with Dapeng Laser

Advancements in 3D Laser Cutting and Welding

The realm of 3D laser technologies is witnessing remarkable advancements, ushering in new possibilities across various industries. As industries continue to evolve, Dapeng Laser's cutting-edge advancements in 3D laser cutting and welding equip manufacturers to enhance precision and productivity. By integrating robust capabilities like three-dimensional five-axis cutting and welding, Dapeng ensures they remain at the forefront of innovation. Industry experts forecast that future trends in laser technology will redefine manufacturing capabilities, with 3D laser systems leading the transformation. Dapeng's commitment to research and development ensures they continually meet the growing demands for more comprehensive solutions in sectors such as automotive, aerospace, and beyond, thereby keeping their competitive edge sharp.

Training and Support for Seamless Technology Adoption

Dapeng Laser's commitment to seamless technology adoption is evident in their robust training and support programs designed to empower clients fully. Recognizing the complexities involved in transitioning to advanced laser technologies, Dapeng provides extensive resources, including detailed materials and targeted workshops. These initiatives ensure that businesses can navigate the changeover process smoothly and efficiently. Notably, Dapeng's customer satisfaction statistics highlight significant performance improvement post-training, underscoring the effectiveness of their support systems. Companies report enhanced operational productivity and a meaningful return on investment, thanks to Dapeng's comprehensive approach to technology integration and continuous support.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA