Exploring Dapeng Laser: A Model in the Industry with Full - Process Services from R&D to After - Sales

Dapeng Laser's Role in Advancing the Laser Industry

Pioneering Laser Industry Services Across Sectors

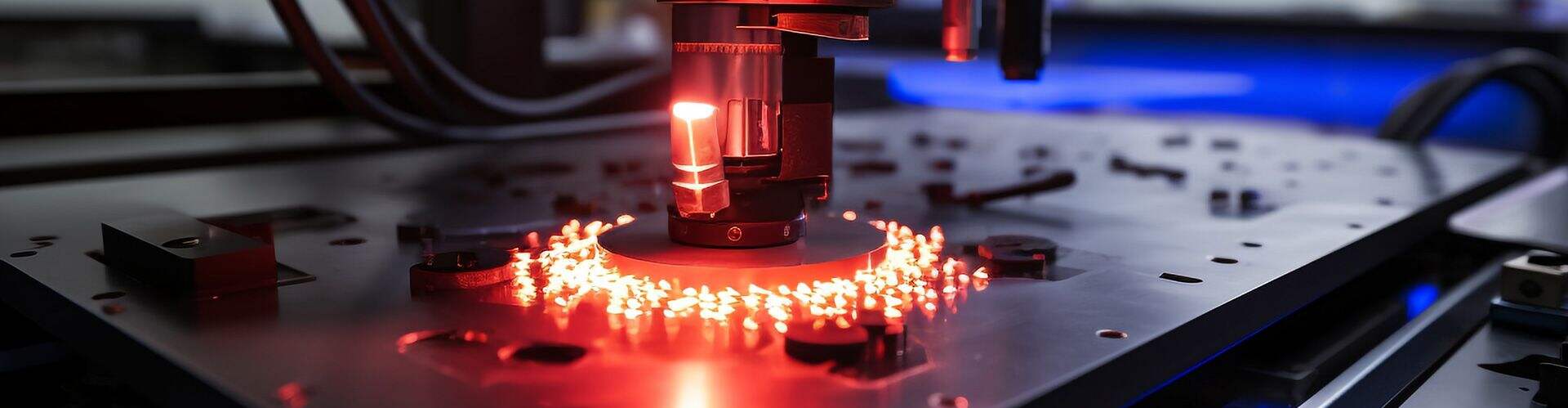

Dapeng Laser has positioned itself as a leader in delivering laser industry services across various sectors, including automotive, aerospace, and medical devices. The company, known for its cutting-edge laser technology, provides customized solutions tailored to meet specific industry needs, enhancing operational efficiencies. Dapeng Laser's commitment to innovation and technology integration has led to strategic partnerships with leading enterprises, ensuring it stays at the forefront of the laser industry. Collaborating with top firms allows the company to incorporate the latest advancements in laser technology, maintaining its reputation as a pioneer in this field. This strategic positioning not only advances Dapeng's offerings but also sets benchmarks for quality and efficiency in the laser market.

Driving Efficiency in Manufacturing with Fiber Laser Solutions

Dapeng Laser's fiber laser solutions are transforming manufacturing processes by enhancing speed and precision. These solutions offer superior energy efficiency and lower operational costs, attracting modern manufacturers looking to streamline their operations. The adoption of automated systems equipped with fiber lasers enables significant improvements in production lines, allowing scale-up of operations without compromising on quality. Industry reports highlight that companies utilizing advanced fiber laser technologies have seen up to a 30% increase in productivity, underlining the importance of such innovations in today's competitive market. With fiber laser cutting machines and technologies, manufacturers can optimize output and meet increasing demands efficiently, making Dapeng Laser's offerings indispensable in the realm of manufacturing.

Cutting-Edge R&D and Fiber Laser Innovations

Fiber Laser Source Development for Precision Applications

Investments in research and development have firmly positioned Dapeng Laser at the forefront of fiber laser source innovation, particularly for precision applications in industries such as aerospace and advanced manufacturing. The company focuses on creating high-performance fiber laser sources that offer superior cutting quality and enhanced energy efficiency. Such advancements allow companies to not only improve operational precision but also significantly reduce energy costs. According to industry experts, advancements in fiber laser technology result in less material waste and bolster manufacturers' sustainability initiatives. By maximizing output and minimizing waste, Dapeng Laser ensures that its clients remain competitive in a progressively eco-conscious market.

Integrating Water Chiller Systems for Optimal Performance

Dapeng Laser places substantial emphasis on the integration of water chiller systems in their laser machines, recognizing the critical role of optimal cooling in maintaining peak performance. Water chillers help prevent overheating of laser components, which is indispensable during prolonged operations and in high-demand applications. User experiences have consistently shown a direct correlation between effective water chiller systems and reduced maintenance costs, thereby improving the return on investment (ROI) for businesses. By enhancing operational efficiency, these systems ensure sustained performance and reliability of laser machinery, crucial for industries that require continuous high-power output and precision such as fiber laser cutting machine and tube laser cutting machine operations.

Full-Process Services: From Prototyping to Implementation

End-to-End Solutions: Design, Testing & Production

Dapeng Laser offers a comprehensive range of end-to-end services that facilitate a smooth transition from design to production, ensuring that clients can meet even the tightest deadlines. The streamlined workflow is particularly beneficial for industries where time-to-market is critical, as it minimizes disruptions and accelerates the overall process. According to recent statistics, organizations that engage full-process services such as those offered by Dapeng Laser can reduce their time-to-market by as much as 40%, significantly enhancing their competitiveness in fast-paced markets. This reduction in lead time can give companies a critical edge, ensuring their products reach consumers ahead of the competition.

To achieve this seamless transition, Dapeng Laser's expert team conducts meticulous testing at the prototyping phase, ensuring client specifications are fully met and reducing the probability of costly reworks. By addressing potential issues early in the production cycle, companies can maintain high standards of quality without sacrificing efficiency. This approach not only boosts production efficacy but also aligns the final output with the client's business goals, thus safeguarding against unnecessary expenditure and optimizing the use of resources.

Customized Tube Laser Cutting Machine Configurations

Dapeng Laser is well-recognized for providing customized tube laser cutting machine configurations tailored to meet specific manufacturing needs. These machines are integral for industries demanding precision and adaptability, such as furniture manufacturing and automotive parts production. They can handle a variety of tube sizes and materials, thereby offering flexibility that aligns with diverse industry requirements. The ability to adjust machine settings to the unique specifications of each project underscores the adaptability of Dapeng's solutions, making them indispensable in dynamic operational environments.

Feedback from clients consistently points to high levels of satisfaction with the performance and customization options of Dapeng's tube laser cutting machines. These machines not only enhance precision in cutting techniques but also increase operational efficiency by minimizing downtime and maximizing output. Companies that have integrated these laser cutting solutions into their workflows report improved product quality and a greater return on investment. Consequently, Dapeng Laser's customized solutions empower businesses to meet specific operational challenges while maintaining superior standards of performance and efficiency.

Industry Applications of Dapeng Laser Technology

Fiber Laser Welding Machine Capabilities in Automotive Manufacturing

The integration of fiber laser welding machines in automotive manufacturing has revolutionized production by significantly improving both quality and speed. These machines offer superior joint quality, essential in maintaining rigorous safety standards, as they reduce the likelihood of defects prevalent with traditional welding methods. This enhanced precision ensures that manufacturers can meet the demands of the global market more effectively. Case studies have consistently shown that automotive manufacturers who incorporate fiber laser welding technologies can experience up to a 25% increase in production efficiency. This boost not only accelerates production timelines but also plays a critical role in maintaining competitiveness in a fast-paced industry.

Large-Scale Metal Processing with Robotic Laser Systems

Dapeng Laser's robotic laser systems are engineered to facilitate large-scale metal processing with exceptional precision, making them invaluable for industries such as aerospace and heavy machinery. These systems are highly adaptable, capable of executing various tasks from cutting to welding, which enables significant cost savings and operational efficiency. The flexibility of robotic laser systems allows organizations to transition seamlessly between different production needs without compromising on quality or speed. Industry trends indicate that employing robot-assisted laser processing can enhance production capability by up to 50%. This technological advancement underscores its vital role in advancing the capabilities of modern industrial landscapes.

Customer-Centric After-Sales Support and Maintenance

24/7 Technical Assistance for Laser Equipment Parts

Dapeng Laser emphasizes customer satisfaction through comprehensive 24/7 technical support for laser equipment. This ensures clients can maintain their operational capabilities without interruptions, crucial for any production environment. Access to expert assistance allows businesses to troubleshoot issues promptly, minimizing costly production downtimes. Feedback from clients often highlights the value of this round-the-clock support, indicating Dapeng Laser's commitment to ongoing service beyond the initial product delivery. Such testimonials reflect the company's dedication to providing reliable technical assistance that keeps operations running smoothly, underscoring its pivotal role in customer maintenance strategies.

Predictive Maintenance Programs for Fiber Laser Cutting Machines

Dapeng Laser advances industrial efficiency with its predictive maintenance programs specifically for fiber laser cutting machines. These programs empower companies to monitor equipment health proactively, identifying potential failures before they occur. This foresight significantly reduces maintenance costs and extends the lifespan of critical machinery. An industry analysis reveals that businesses incorporating predictive maintenance strategies cut maintenance expenses by an average of 20%. This reduction not only represents financial savings but also enhances operational reliability. By continually investing in these forward-thinking programs, Dapeng Laser highlights the importance of preemptive solutions in industrial maintenance, ensuring machines perform efficiently over extended periods.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA