Types And Selection Guide For Laser Sources

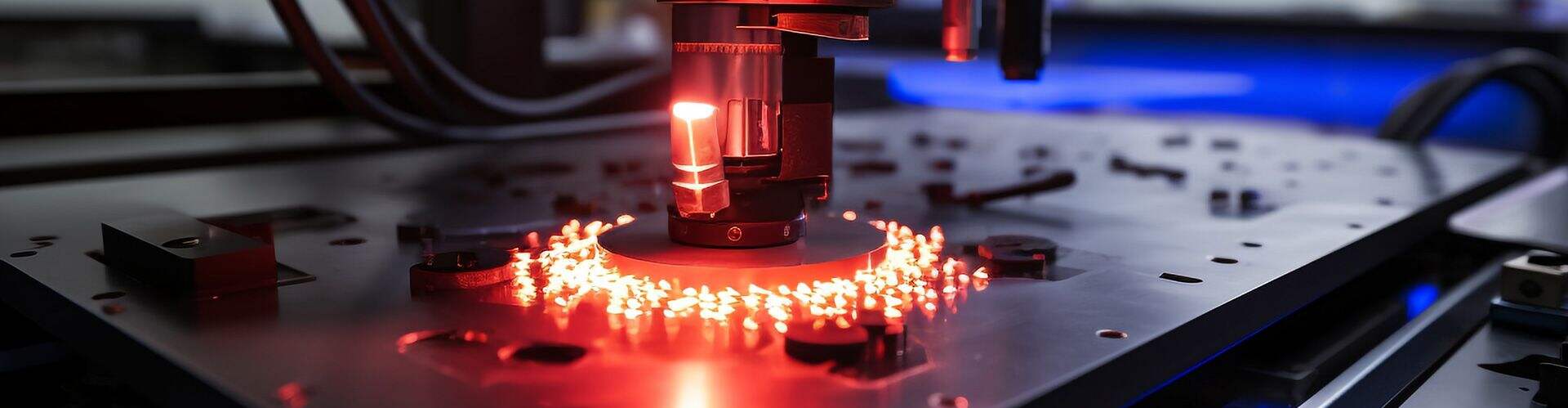

Laser sources are viable and essential devices in many branches of industry, health care, and telecommunications. The abbreviation 'laser' means light amplification by stimulated emission of radiation and these devices produce light that is coherent and directed. When using the different kinds of laser sources available, it’s easy for the users to select the most appropriate technology for their needs.

Variety Of Laser Sources Available For Use

Solid Party Lasers

Solid-state lasers are laser systems that use a solid medium as the gain material, such materials include ruby quartz and neodymium glass. These lasers are usually very durable and have a high power output. They are especially popular in the field of cutting and welding because of the high efficiency of the lasers in the production of the light beam which can be focused.

Gas Lasers

Gas lasers, including carbon dioxide (CO2) lasers, employ gases as the lasing medium. CO2 laser cutting machines are commonly used to cut and engrave non-metal materials, especially wood, plastics, and other such materials. Their long wavelengths enable them to cut deeper into the materials and hence these types of lasers are very effective in thick substrates.

Fiber Lasers

Fiber lasers are made by means of embedding rare earth-doped optical fibers into the laser cavities as gain media. Small fiber dimensions and efficiency allow them to get high laser beam quality so that they are able to perform processes precisely in the automotive and aerospace industries. They are widely used for both cutting as well as marking applications due to their flexibility and durability.

Diode Lasers

A diode laser is a semiconductor device that converts electricity into beams of light. They are small in size, consume less power, and can generate light of different wavelengths. Typically used in devices for consumers and in the medical field, diode lasers are also conquering the industrial market. They are used for laser marking and surface treatment in particular.

Factors to Consider When Selecting a Laser Source

Application Requirements

The first step in selecting a laser source is understanding the specific application needs. Consider factors such as material type, thickness, and the desired finish. For example, CO2 lasers excel at cutting non-metals, while fiber lasers are preferred for metals.

Power and Efficiency

Lasers are of different sources and their output can be optimized for laser effective efficiency. The greater power is useful in cutting thick products so as to dispel long operating hours costs. Power requirements must be well-balanced against energy efficiency to achieve the desired output.

Selecting the right laser source requires careful consideration of application needs, power and maintenance features. Different types of lasers are appropriate for different tasks as they have different advantages. At DP laser, we deal with laser solutions of high quality that are needed in various industries.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA