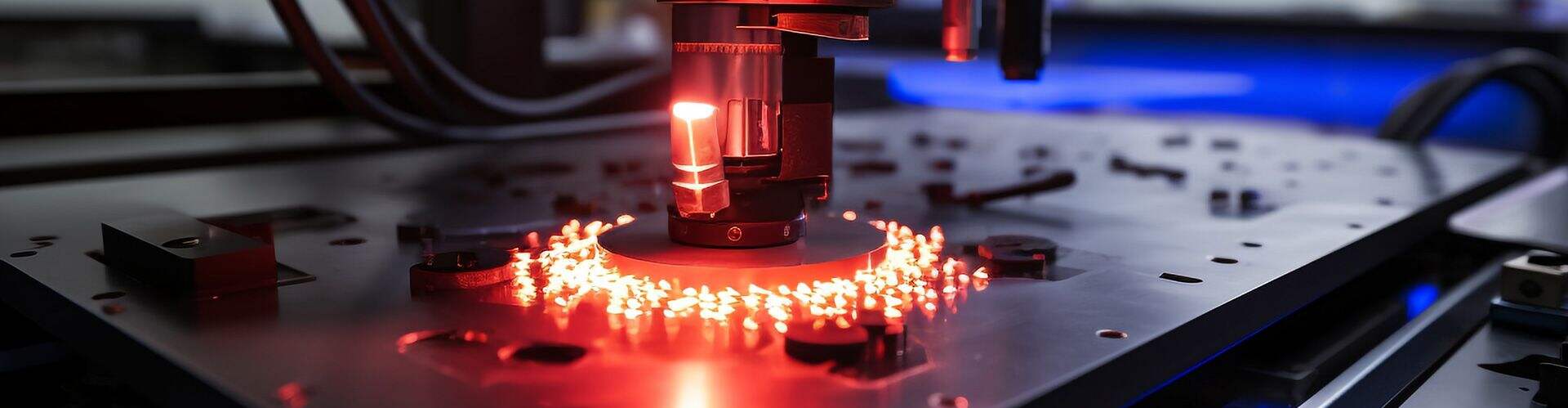

Tips To Maintain Your Laser Spot Welding Machine’s Peak Performance

To keep your laser spot welding machine in good working order, it is necessary that you clean and inspect the unit regularly. Dust or dirt can affect its optics and decrease efficiency, or worse still cause damage. When cleaning, use appropriate tools together with solutions such as a cleaning lens cleaner among other optical parts cleaners. Additionally, check if all sections of the equipment are worn out anywhere through continuous checking which should be followed by immediate fixing before they bring about any breakdowns in its functioning.

Laser Alignment Checking And Maintenance

Proper alignment of the laser beam must be achieved to attain consistent weld quality. Always check whether there is any misalignment within the system, then adjust accordingly so that correct results can still be obtained during the welding process. If alignment is not done well enough irregular welds may result causing poor utilization of this machine's overall performance Most laser spot welders have built-in systems for checking alignments but manual checks combined with frequent adjustments are still needed.

Monitoring Cooling Systems

Cooling systems play a critical role in preventing overheating that could damage or reduce the lifespan of your laser spot welding machines. Ensure coolant levels are right while at the same time confirming proper cooling fans functioning along with other related components/systems. Internal parts might easily get spoilt if too much heat is generated within an assembly thus greatly lowering productivity level This means these areas should receive more attention by being serviced regularly so that they always operate within desired temperature ranges.

Updating Software And Firmware

Always keep the software’s firmware up-to-date because failure to do so can impact the general performance ability of a Laser Spot Welder appliance There could be several updates released by manufacturers towards improving capabilities or fixing bugs among other things.. Check whether any available updates need installation thereby enabling this device to work with the most recent modifications made on it.

Conducting Periodic Calibration

Calibration should be done frequently to verify the accuracy of a laser spot welding machine. Regularly test the equipment to determine whether it is still performing within specified limits or not. This continuous calibration ensures that such welds attain their highest quality and consistency levels throughout thus minimizing the chances of having defects in finished products while also increasing overall manufacturing efficiency.

DP Laser provides reliable accurate quality laser spot welding machine. For more details about these machines’ maintenance procedures and optimization techniques . With cutting-edge technology coupled with an experienced technical support team we can assist you achieve faster superior welding operations within your production line without compromising on standards!

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA