The Role Of Robot Laser Welding In Automated Manufacturing

The application of the welding laser through robots in the automated production process is becoming widely used in industries. This is because welding operations are greatly improved in quality and efficiency as a result of combining the accuracy of laser technology with robotics. In this paper, I will discuss the various aspects of robot laser welding and its use in modern industries and operations.

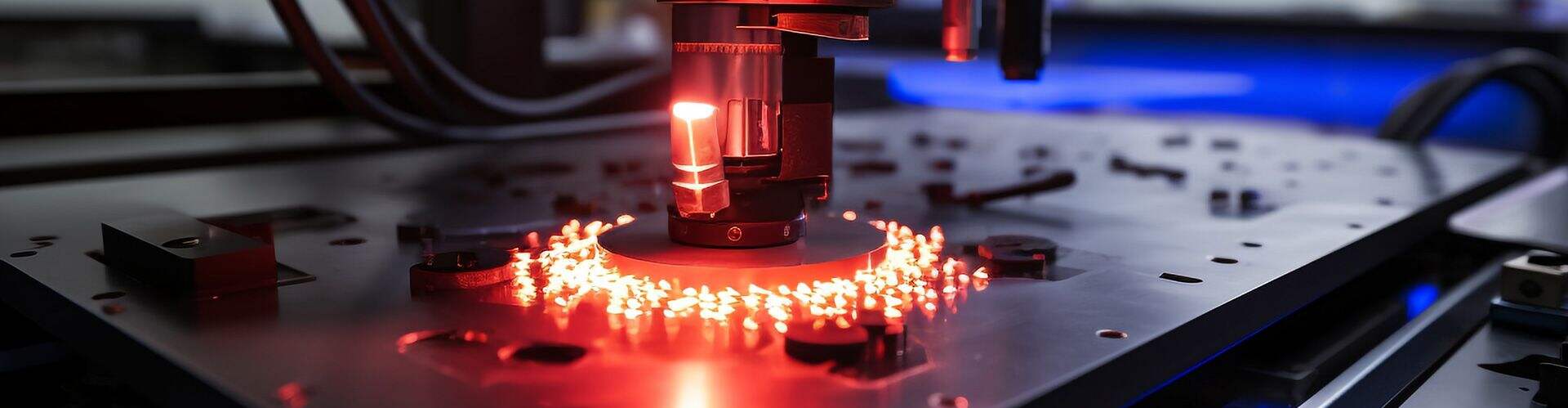

How Robot Laser Welding Works

The joining of materials using a laser beam is what is referred to as robot laser welding. To eliminate human interference and improve efficiency robotic arms which are programmed to move in specific ways to complete specific welding tasks are used. This is suitable for even very complicated geometries because the welding process is consistent. An additional laser's high energy density allows it to rapidly weld components with low thermal distortion which is suitable for fragile parts.

Advantages of Robot Laser Welding

One of the major benefits of using robot laser welding is the process speed. The heating and cooling cycle can be time-intensive, but ultimately, it results in the reduction of processing time, which translates into better production rates. In addition, laser welding is very accurate in the quality of welded joints and therefore some of the welded parts may require less welding to be done even after they have been completed, resulting in waste minimization. It is a relatively economical solution due to this.

Merger of Technologies

Robot laser welding technology is advancing all the time and it can be applied across industries such as automotive, aerospace, and electronic industry. It is used in the automotive industry to produce lightweight structures and components to improve fuel consumption and performance for example. With Laser Welding, there is precision required when dealing with laser welding and this is important for dealing with fragile parts in the electronic industry. This flexibility ensures that it is fitted for any automated assembly line.

Protection and Consistency

Whenever there is a production activity, safety concerns are always to be considered. There are many safety aspects that robot laser welding operators should consider within the welding enclosure as well as safety sensors which are built in the system. Furthermore, robotic systems are reliable hence human error is reduced improving the quality received from end output. The blend of the two which is consistency and safety goes on to make the workplace even more secure and efficient.

In conclusion, I see robot laser welding as one of the apparent disruptions we see in automated production processes because it is fast, precise as well as can be used in various industries. Hence, to the ever so, fast-evolving industries embracing efficiency and dependability in their welding processes is going to be the order of the day. Hence, for efficient robot laser welding units, I will suggest DP Laser

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA