Technical Breakthroughs and Challenges in Robot Laser Welding

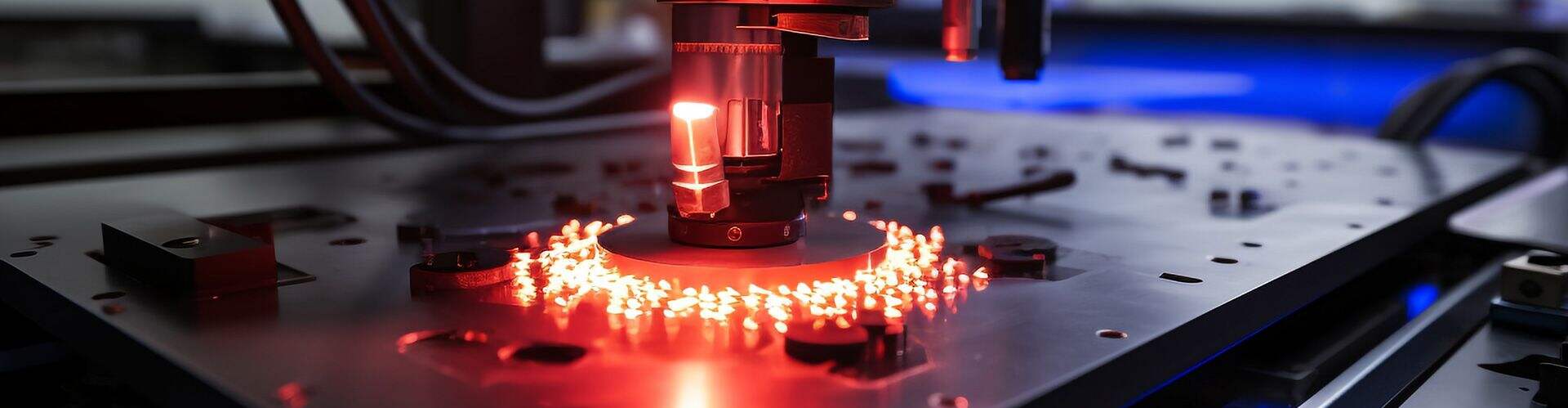

The welding of components using robot laser welding has virtually changed the world of production and processes with high speed, accuracy and flexibility. DP Laser, a company dedicated to robot laser weldings, has also achieved certain developments in the design of robust robotic laser welding systems. Let’s delve into the technical innovations and issues in this rapidly advancing area of research.

Technical Breakthroughs

Expansion of joint capability

Thanks to also their precision laser scanners, DP Laser has managed to create a series of 6-axis robot laser welding machines that are capable of welding joints buried in diffcult to access regions. Adaptive welding technology ensures that the welding joint is precise, accurate and can be repeated.

Reduction of cycle time

Because of the use of lasers coupled with robotics, it has been possible to increase welding speed tremendously. The goal of the systems developed by DP Laser is the reduction of cycle times to allow manufacturers or consumers to create more parts within a short time.

Growth in Flexibility

DP’s Robot laser welding systems also add value via the versatility and flexibility they posses. With these systems different types of welding processes can be carried out with multiple materials and of varying geometric shapes.

Automated Integration

There are, in respect to laser welding, a number of areas that DP Laser has progressed in automating. All of the approaches produce the same process that is the automatic feed of parts, then the parts are cleaned, then they are welded together which excludes the human operator completely.

Challenges

Tricky Integration

Integrating robot laser welding systems in the existing process flows and setups is a challenge. It is a matter of proper organization and scheduling so that the system does fit well and improves production.

Material Handling

The challenged posed by laser welding systems is to be able to position and manipulate large and irregularly shaped components for welding. DP Laser tackles this challenge by providing fully integrated systems that are designed for ease of material handling for each application.

Cost Considerations

The cost of robot laser welding technology is quite significant when initially acquired. However, DP Laser’s systems are constructed with the goal of attaining a short investment payback period through enhanced efficiency and decreased manpower cost.

Training and Expertise

Specialized training is crucial; both in welding and maintenance of the robotic laser welding machines. Workforce training is also an important activity of management which DP Laser plans to utilize in order to ensure that operators get the full capabilities of their systems.

Conclusion

DP Laser’s advanced robot laser welding prototypes set the trend for the advancement in this type of welding. They combine accurate, fast and flexible operations which are all desirable for any manufacturer approaching different competitive welding tasks. Admittedly, there are hurdles to cross but most importantly the advantages of this technology development are solid. DP Laser is ready to meet the requirements of clients who are looking for robot laser welding solutions to achieve the technological breakthroughs that bring success forth.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA