Technical Advantages Of Fiber Laser Welding Machines

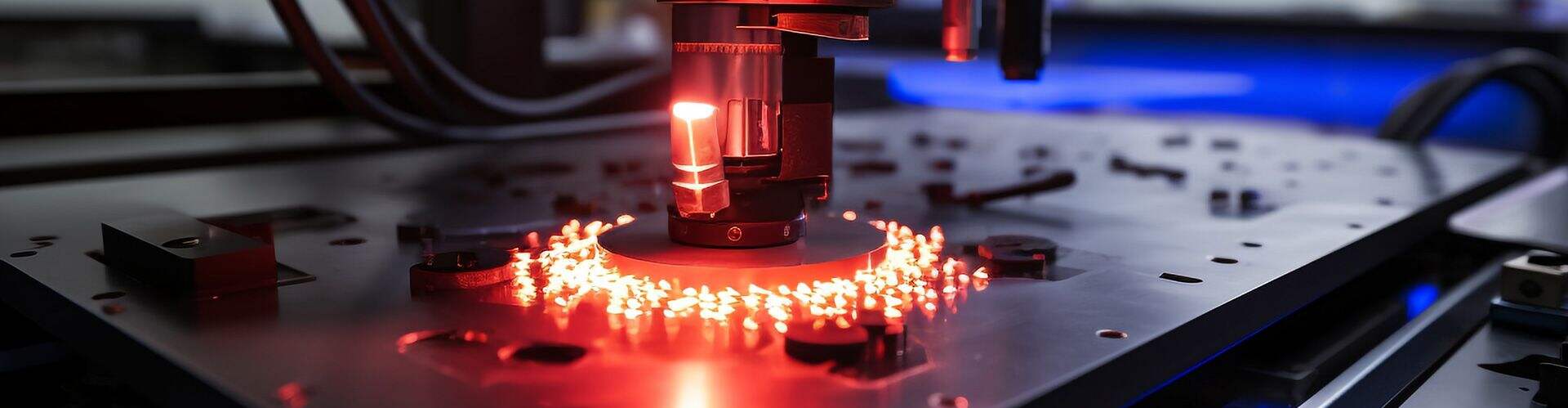

Industries that demand high accuracy and efficiency in welding applications have progressively embraced fiber laser welding machines. These machines which have modern technology and excellent performance over almost all welding processes have more technical advantages. In this paper, we will examine the technical strength of fiber laser welding machines and show the extent to which offerings from DP Laser can cope with and surpass your industrial expectations.

Precision and Consistency:

One of the most notable advantages of fiber laser welding machines is the capacity to produce constant and accurate welds. The machines utilize high-power fiber laser as the energy source that offers selection on the manner of welding. Utilizing a focused laser beam permits the input of heat to be in a small, centralized area, preventing heat that affects surrounding materials and even insider effects from reaching undesirable distances. This evaluation implies consistent and repeatable end-products, making the fiber laser welding machines recommendable to processes with higher quality tolerance levels.

Speed and Efficiency:

Fiber laser welding machines have amazing speed effectiveness and in fact, they are faster and more effective than the conventional forms of welding. The machines have higher power outputs and record faster processing rates and thus can carry through joins in a matter of seconds. The increased speed will not only increase the quantity of work done but even reduce the cost of working since energy and wear and tear on the machines are lower. DP Laser’s fiber laser welding machines are constructed to improve workflow efficiency and in turn, increase throughput within the business in investments aimed at involving the manufacturing of processes.

Versatility and Adaptability:

The versatility of fiber laser welding machines is yet another technical merit which makes them stand out from the competitors. These machines can cut and weld metals, alloys, and even other materials which are usually not cut using lasers. Adjustable parameters like power, speed, and focal point, make the welding operation more specific to materials and applications. This flexibility means fiber laser welding machines can be useful across any enormous fields whether automotive or aerospace or electronics or even medical device production factories.

Quality and Reliability:

According to weld quality, fiber laser welding machines are the best. The lower the porosity and spatter, the more presentable and clean the weld finishes will be. Last but not least, the reliability of the machines ensures that the preferred welds can be put under strenuous tests and operational conditions. Because of the interest in quality engineering, DP Laser quality control of the fiber laser welding machines is implemented up to the maximum quality standards of the relevant industry.

Safety and Ergonomics:

Fiber laser welding machines combine efficacy with safe and ergonomic characteristics when compared to other welding techniques. The closed design of these machines ensures that exposure to radiation and fumes is minimized. Also, due to the fiber laser welding being hands-off, difficult contraction is not needed from operators enhancing safety for the workers. With safety and ergonomics as a priority, the fiber laser welding machines from DP Laser, do not compromise on the efficiency of the operators.

The advances in the design and construction of fiber laser machines make them relevant in present-day manufacturing processes. For instance, dense and fast welding and construction without ugly seams that are permanent and barely visible, mobility, safety, and quality surpass the classical advantages of welding processes. DP Laser offers laser fiber welding machines that possess all these advantages to any business that is looking for such high-performance equipment.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA