Key Points for Installation and Commissioning of Fiber Laser Welding Machines

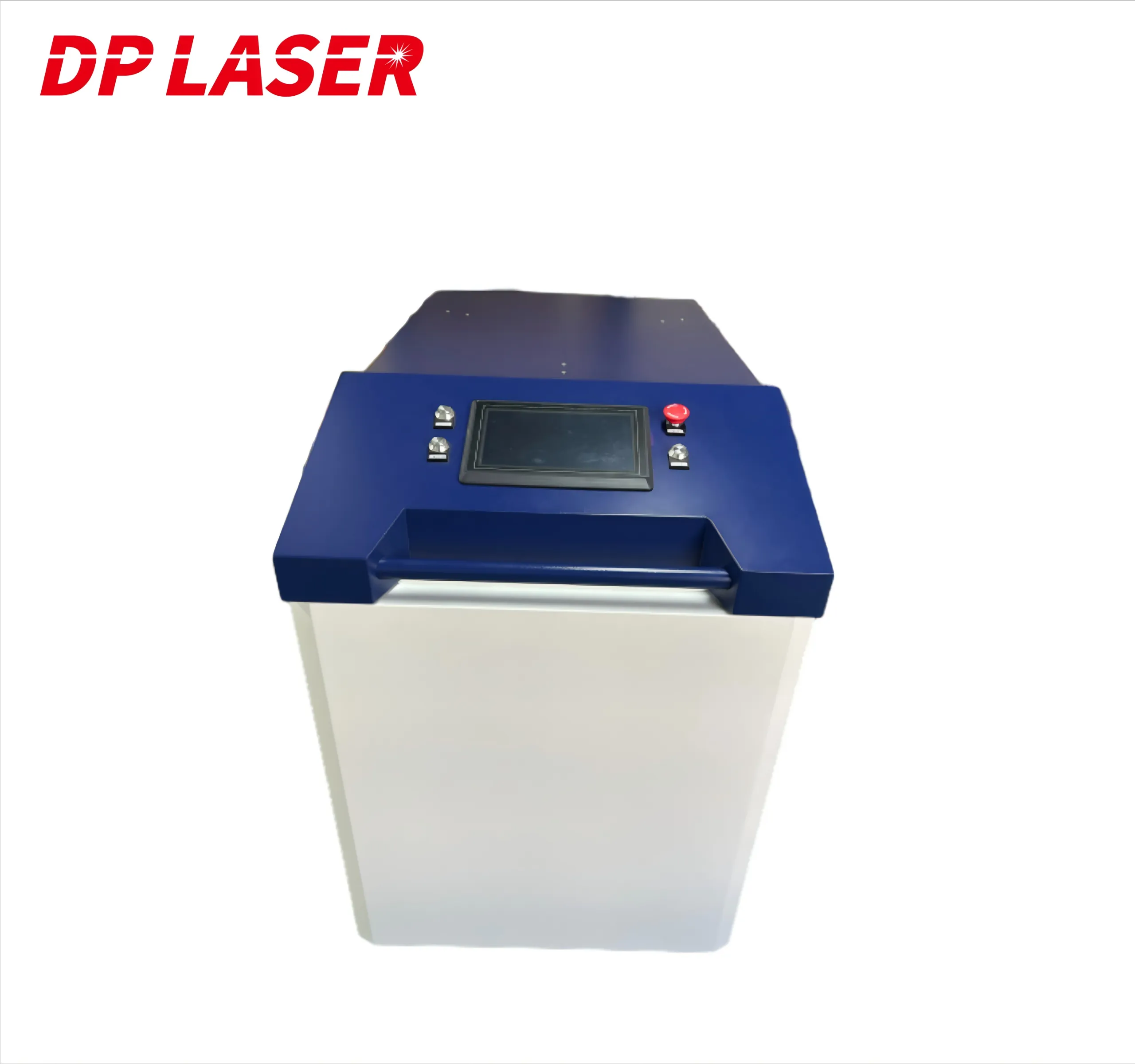

Fiber laser welding machines have become indispensable tools in modern manufacturing, offering precision, speed, and efficiency in welding applications. DP Laser, a leading provider of fiber laser technology, emphasizes the significance of proper installation and commissioning to ensure the machines operate at peak performance. This article outlines the key considerations for the installation and commissioning of fiber laser welding machines, highlighting the steps necessary for a successful setup.

Site Preparation:

Ensuring an Appropriate Environment

Before installing a fiber laser welding machine, it is crucial to prepare the site adequately. This includes ensuring that the area is clean, free from debris, and has sufficient space for the machine and its peripherals. The site should also have a stable power supply and appropriate ventilation to dissipate heat generated during operation.

Machine Placement:

Positioning for Accessibility and Safety

The placement of the fiber laser welding machine is critical for both accessibility and safety. The machine should be positioned in a manner that allows for easy loading and unloading of materials, as well as convenient access for maintenance and repair. Safety considerations include ensuring that the machine is not obstructing emergency exits or walkways.

Leveling and Grounding:

Achieving Stability and Preventing Electrical Interference

Proper leveling of the fiber laser welding machine is essential to prevent vibrations that could affect the welding accuracy. The machine should be securely anchored to the floor to maintain stability during operation. Additionally, grounding the machine is crucial to prevent electrical interference and protect against potential electrical hazards.

Calibration and Testing:

Ensuring Precision and Consistency

Calibration is a vital step in the commissioning process, ensuring that the fiber laser welding machine delivers consistent and precise results. This involves adjusting the laser beam parameters, such as power and focus, to match the specific welding requirements. Thorough testing should be conducted to verify the machine's performance and identify any potential issues before full-scale production begins.

Operator Training:

Empowering Users for Safe and Effective Operation

Training operators on the proper use and maintenance of the fiber laser welding machine is imperative. This training should cover safety procedures, machine operation, and troubleshooting techniques. Well-trained operators can maximize the machine's capabilities and minimize the risk of accidents or equipment damage.

Maintenance and Support:

Ensuring Long-Term Reliability

Regular maintenance is key to maintaining the reliability and longevity of fiber laser welding machines. DP Laser provides comprehensive support, including maintenance schedules and service contracts, to ensure that the machines continue to perform optimally. Prompt technical support is also available to address any issues that may arise during operation.

Conclusion:

Emphasizing the Importance of Installation and Commissioning

In conclusion, the installation and commissioning of fiber laser welding machines are critical processes that require careful attention to detail. By following the key points outlined in this article, manufacturers can ensure that their machines are set up for success, delivering the precision, speed, and efficiency that fiber laser welding is known for. DP Laser's commitment to quality and customer support ensures that businesses can rely on our fiber laser welding machines for years to come.