Investigating Fiber Optic Laser Cutters: Strengths And Uses

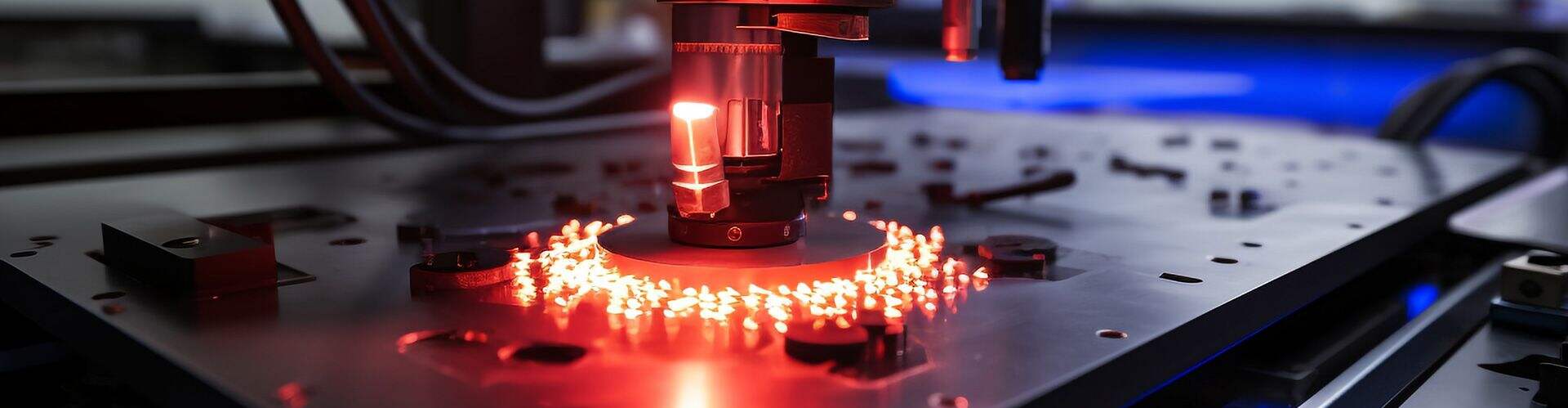

Fiber optic laser cutters have changed modern manufacturing by making cutting more accurate, but they also come with many other benefits that can be applied in different industries.

Strengths

The most essential benefit of fiber optic laser cutters is their unheard-of precision. The focused beam enables intricate cuts without much exposure to heat thus reducing the chances of material distortion. This is particularly important for sectors like aerospace or electronics where even the slightest mistakes can affect performance.

Additionally, these lasers are known for their efficiency and speed. They can easily slice through a wide range of materials quickly; ranging from non-metals such as plastics and composites to metals like stainless steel or aluminum etcetera. This versatility makes them useful in various manufacturing processes which leads to faster production cycles and shorter lead times.

Another advantage is lower operating costs associated with using fiber optic laser cutters. Traditional cutting methods consume more power than these devices do while still performing at par with them; this coupled with solid-state construction that requires little maintenance translates into higher cost-effectiveness thus better profits for manufacturers.

Applications

Fiber optic laser cutters find numerous uses within multiple industries too. For example, during automotive manufacturing, they are employed mainly for accurate cutting of chassis components as well as body panels among others related to this sector. In electronics production, small intricate circuit boards can be made thanks to their help along with microelectronics too being produced under the same roof where such equipment exists. In the medical field on the other hand some surgical instruments may need very fine edges achieved only through the use of fiber optic lasers while other areas deal with creating precise shapes inside medical devices which again calls for a high level of accuracy provided by these pieces of technology.

Moreover, architects rely heavily upon fiber optics when coming up with fancy designs involving metals; likewise, those working within sign sign-making industry find custom metal signage creation tasks very easy due to the availability of fiber optic laser cutters. This means that through them designers and architects can actualize their desires by producing complex patterns or shapes efficiently thus enhancing the beauty value attached to buildings as well as signs that represent different establishments.

Conclusion

To sum it all up Fiber Optic Laser Cutters have brought about precision, speed, and versatility in the manufacturing industry. They can cut through different types of materials with high levels of accuracy within short periods thereby revolutionizing various sectors worldwide. As technology advances so does the capability of these machines thus leading to more innovation throughout manufacturing processes around the globe.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA