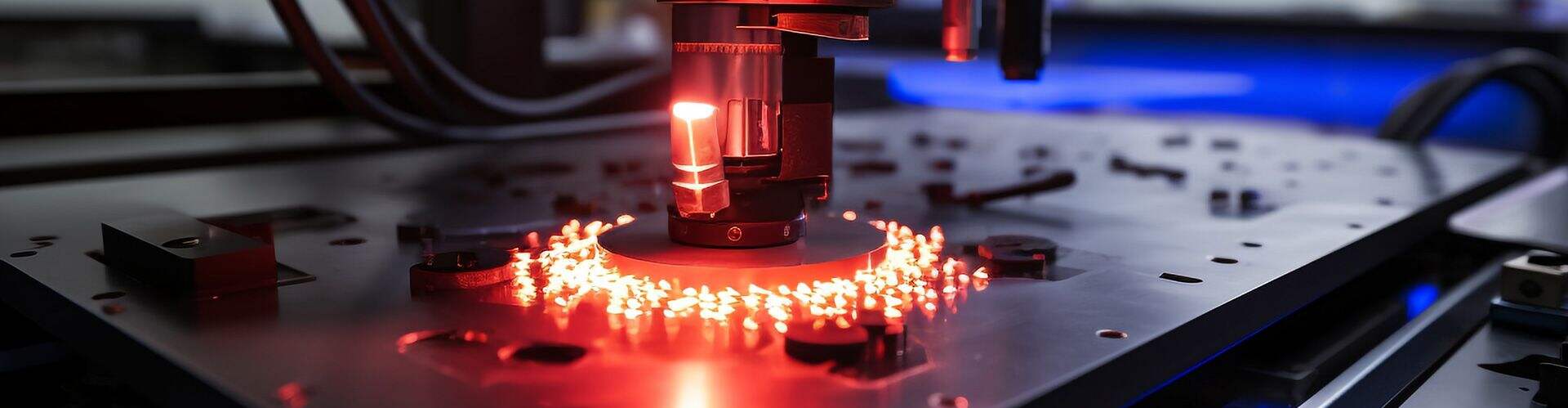

Boosting Performance Through Modern Laser Welding Machines

The laser welding machines are equipped with highly focused laser beams that join materials very accurately and at high speed. This technology is advanced in a way that it can make welds of high quality with minimal thermal distortion hence applicable in delicate and complicated tasks. Laser welding machines have been shown to greatly improve performance across many types of manufacturing operations by increasing speed, precision, and overall weld quality.

Important Characteristics for Optimum Performance

For maximum performance using laser welding machines, it is important to consider some key features. First, evaluate the power and wavelength of the laser; higher power enables deeper penetration as well as faster welding speeds while shorter wavelengths enhance material compatibility and efficiency. Also, look out for machines having precise control systems coupled with advanced optics which ensure consistent weld quality throughout plus the least possible heat-affected zone (HAZ).

Efficiency and Speed

One great advantage of using laser welding machines in welding is their ability to increase efficiency and speed. These equipments perform much quicker than conventional methods thereby reducing the production time required for a given volume of workpiece being welded together in addition to increasing throughput rate. Features such as automated handling systems together with real-time process monitoring help save on labor costs by minimizing the need for manual intervention besides providing the best conditions needed for optimal welding throughout the entire operation.

Material Versatility

Laser welders are known to be versatile when it comes to handling different types of materials. They can easily join metals, and plastics among other things at high accuracy levels making them useful in a wide range of applications too. Ensure that you choose a machine that is compatible with your intended workpieces’ composition as well as offers adjustable settings capable of accommodating various thicknesses or kinds of materials during the fabrication process.

Maintenance Support

Regular maintenance support plays a critical role in maintaining good performance from any given type or model of such industrial machinery like those used in the laser welding industry sector. It’s advisable therefore always go for brands that provide a full range of service packages including technical support, maintenance guide, and spare parts provision. Proper servicing not only keeps these gadgets running smoothly but also extends their lifespan while preserving weld quality output.

DP Laser offers different types of advanced industrial laser welding machines designed to enhance performance and productivity in various manufacturing processes. These machines have been fitted with the latest technologies, high power output levels as well as exceptional precision which can meet any welding requirement. Visit DP Laser today and find out how our products can help improve your production capacity. Invest in reliable yet innovative laser welders from us to take your welding business to another level.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA