Choosing Dapeng Laser, Embarking on a Win - Win Journey of High - Efficiency Production and High - Quality Products

The Role of High-Efficiency Production in Modern Manufacturing

Meeting Global Demand Through Advanced Fiber Laser Solutions

High-efficiency production is vital in addressing the increasing global demand for manufactured goods, and advanced fiber laser solutions play a significant role in this transformation. Fiber laser cutting machines provide substantial benefits, offering unmatched speed and precision in cutting processes. According to market reports, the fiber laser cutting machine industry is experiencing remarkable growth, with a compound annual growth rate of approximately 5-6%, driven by high-efficiency operations that cater to rising production needs.

1. Advantages of Fiber Laser Cutting Machines:

- Speed: These machines significantly reduce production time compared to traditional methods.

- Accuracy: Ensure precise cuts on various materials, enhancing product quality.

Moreover, advanced fiber laser solutions allow manufacturers to operate at a lower cost and achieve quicker turnaround times, making them more competitive in global markets. Case studies reveal that manufacturers adopting these technologies have improved operational efficiencies and expanded their market reach. This technology is especially beneficial for companies like Automation, which utilize robotic integration to scale production, as seen in the success stories of firms leveraging AI-driven automation.

Reducing Costs While Maximizing Output

Implementing high-efficiency fiber laser technologies enables significant cost reductions in material waste and labor, as companies using these systems report up to 30% savings on production costs. By minimizing manual intervention and optimizing resource utilization, these technologies facilitate economical production processes, which are crucial for sustaining profitability in a competitive market landscape.

1. Cost Reduction Strategies:

- Material Efficiency: Precision cutting reduces waste, optimizing material usage.

- Labor Savings: Automation lessens the need for manual labor, lowering costs.

Maximizing output while maintaining high-quality standards is achievable through adaptive laser cutting solutions, which adjust to different materials and project specifications. This versatility boosts overall productivity without compromising product quality, fostering an environment where efficiency aligns with excellence. The integration of these systems in manufacturing processes exemplifies the industry’s commitment to innovation and productivity enhancement, reinforcing companies' positions in the global arena.

Through these discussions, the essential role of advanced fiber laser solutions in modern manufacturing is evident, underscoring their capacity to drive efficiency, reduce costs, and cater to global demand dynamically.

Technological Innovations Behind Dapeng Laser’s Success

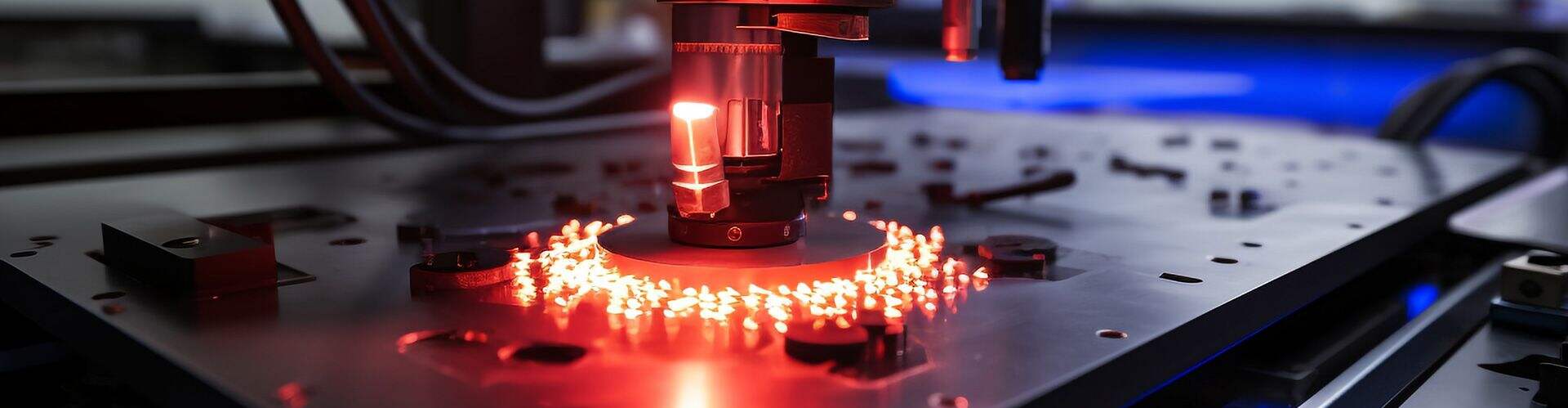

Fiber Laser Cutting Machines: Precision and Speed

Dapeng Laser's success in the modern manufacturing landscape is largely due to its innovative fiber laser cutting machines that offer unmatched precision. These machines adeptly navigate intricate designs, making them exceptionally suitable for advanced industrial applications such as automotive and aerospace sectors. The incorporation of cutting-edge technology ensures precise cuts even in the most complex patterns, enhancing productivity while maintaining high standards of quality. Furthermore, with laser cutting speeds reaching up to 100 meters per minute, these machines significantly accelerate production cycles. This rapid processing capability positions Dapeng Laser's equipment as essentially valuable in high-demand sectors, where both speed and precision are crucial for meeting production targets.

Integration of AI and IoT for Smart Manufacturing

The integration of AI and IoT into manufacturing practices has been revolutionary, enhancing operational efficiency across various sectors. Dapeng Laser leverages these technologies to monitor its machines' performance in real-time and to accurately predict maintenance needs. By employing smart systems, Dapeng Laser reduces downtime and boosts productivity, optimizing workflows to achieve greater cost efficiency—a vital aspect in maintaining competitiveness. Through AI and IoT integration, Dapeng Laser continuously improves operational processes, embodying the essence of smart manufacturing. Supporting statistics from tech firms reinforce the advantages of harnessing intelligent technologies to transform production environments, underscoring their role in driving sustainable and efficient manufacturing practices.

Advantages of Fiber Laser Technology for Quality Assurance

Superior Performance of Fiber Laser Sources

Fiber laser sources are renowned for their superior performance, offering a high power-to-weight ratio that leads to significant energy savings and extended equipment lifespan compared to traditional laser systems. This advantage not only reduces operational costs but also enhances overall equipment effectiveness, ensuring consistency in high-quality output. Research has identified that fiber lasers excel in achieving impeccable cuts across diverse materials with minimal thermal distortion. This precision is crucial for maintaining the integrity of components in precision engineering, where even minor imperfections can have significant impacts. Thus, fiber laser sources prove invaluable in industries where quality assurance is paramount.

Sustainability in Tube Laser Cutting Processes

Sustainability in manufacturing is no longer optional; it is a crucial aspect that companies must incorporate to remain competitive and responsible. The use of fiber lasers in tube cutting processes embodies this shift towards eco-friendly practices by significantly lowering waste production through efficient cutting techniques. Statistics underscore the benefits, showing companies that switch to fiber laser technology can easily meet their sustainability targets. Such advancements not only fulfill environmental obligations but also attract eco-conscious consumers who are increasingly aware and selective of the products they support. By lowering the environmental impact, fiber laser technology helps businesses align with the global push towards greener, more sustainable industrial operations, making it a driving force in today’s manufacturing sectors.

Why Partner with a Leading Fiber Laser Cutting Machine Exporter

Global Compliance and Industry Certifications

Collaborating with a leading fiber laser cutting machine exporter ensures that your business adheres to global compliance standards and industry certifications, which are critical in maintaining international credibility and customer trust. These exporters often possess certifications from reputable organizations such as ISO and CE, reassuring partners about the reliability and quality of their products. Partnering with companies that meet these stringent industry standards allows your business to operate confidently, knowing that you comply with necessary regulatory requirements. This is particularly important in sectors where precision and quality assurance are non-negotiable.

Customized Solutions for Diverse Production Needs

Leading exporters excel in offering customized solutions tailored to the specific needs of diverse industries, making them invaluable partners in optimizing manufacturing processes. They leverage their expertise to design fiber laser machines that meet the unique production requirements of various sectors, enhancing efficiency and productivity within manufacturing setups. For instance, companies that have adopted these customized fiber laser solutions have reported increased output and reduced downtime, demonstrating the machines' adaptability to different industrial applications. This bespoke approach not only caters to specific production demands but also allows businesses to stay agile in the face of changing market conditions. Collaborating with such exporters offers a strategic advantage in maintaining flexibility and efficiency.

EN

EN

AR

AR

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA